A medical device manufacturer in Japan has enabled surgery that had been previously considered impossible by developing the world’s smallest needle. The small company continues making efforts together with physicians to supply quality needles worldwide, thereby saving the lives of patients awaiting treatment.

One spring day 35 years ago, a one-year-old toddler had lost the end of her right middle finger by touching the belt of a sewing machine as her grandmother was pressing the pedal. From that day on, the girl avoided showing her disfigured finger to others, spending every day desperately hiding what she considered a terrible imperfection. At the same time, her grandmother, who had caused the irreversible injury to her grandchild, along with the girl’s parents, who were helpless to prevent the accident, suffered for many years from psychological scars. Yet today, the girl’s right middle finger has a proper tip on the end. Seventeen years after the accident, when she was 18, she had the end of a toe partially removed and transplanted to her finger.

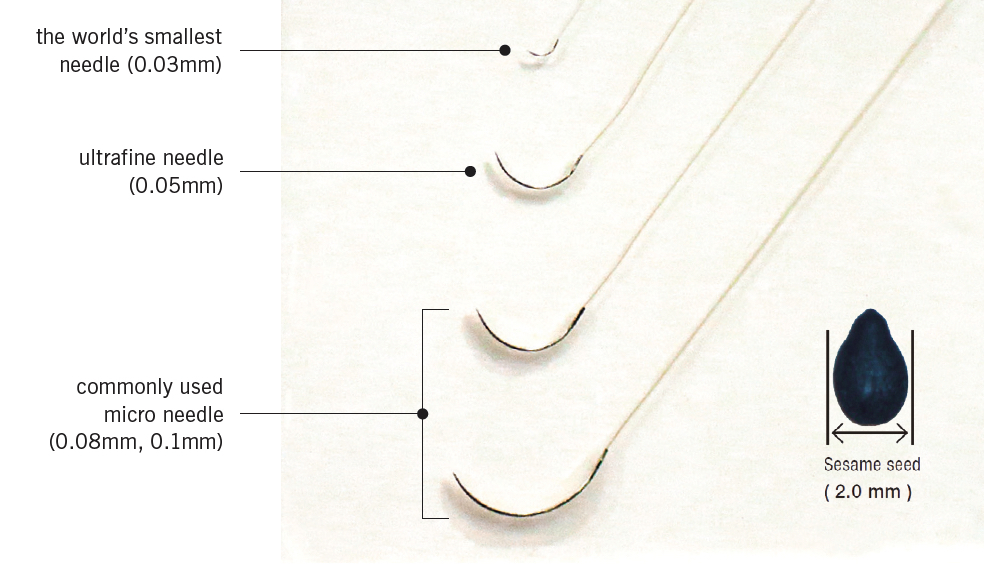

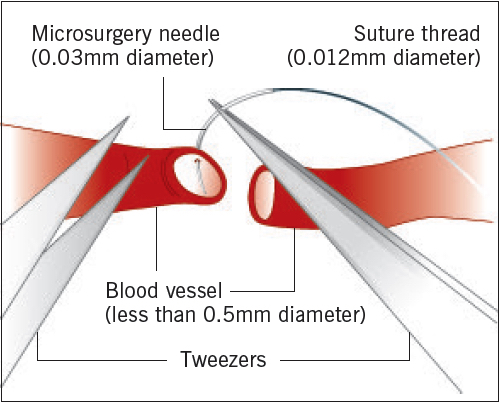

What returned her finger to normal was a new field of plastic surgery, known as microsurgery, that seems like magic. The device that enabled the magic is a needle—developed by Kono Seisakusho Co., Ltd., a Japanese medical device manufacturer—that boasts the smallest diameter in the world, at 0.03mm. The needle has pioneered a new area of operations, including transplants in which blood vessels with diameters of 0.5mm are connected, or operations requiring lymphatic vessels and veins to be connected.

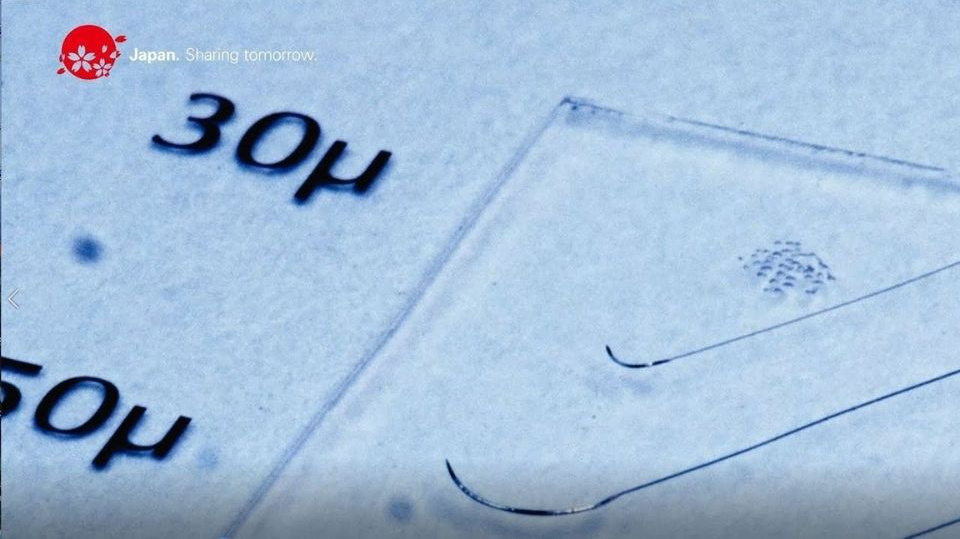

The world’s smallest needle, with a diameter of 0.03mm, guides a suture thread just 0.012mm wide. Of course, it is invisible to the naked eye, so surgeons look through a microscope during operations.

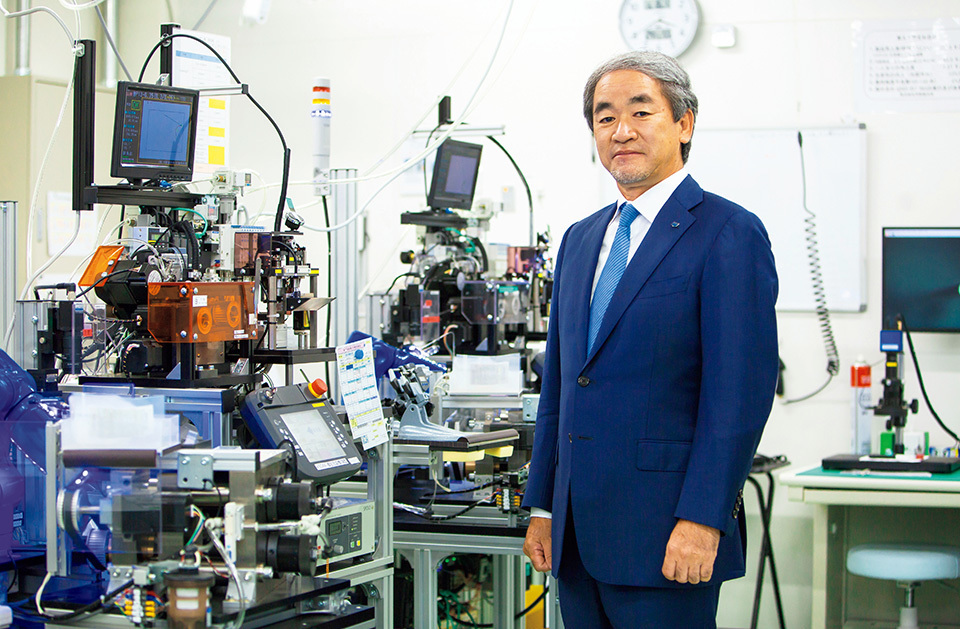

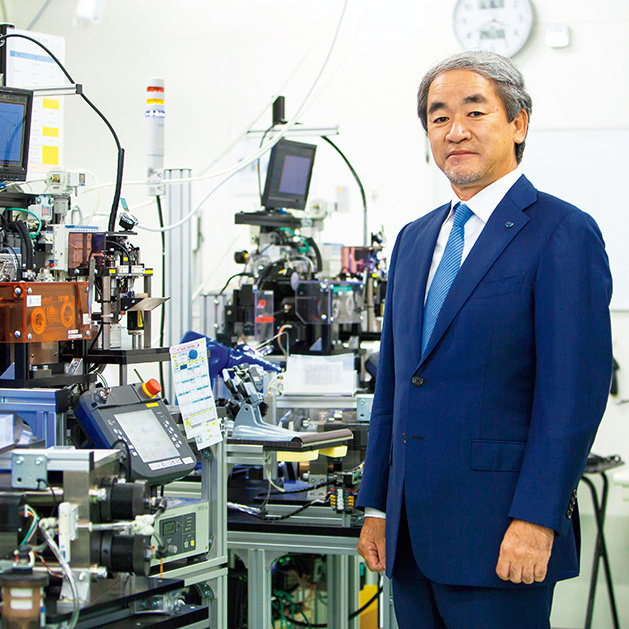

Kono Seisakusho, which mainly deals with suture needles and suture thread, caters to diversifying needs in the medical device sector, with over 10,000 product specifications, of which 4,000 are on the market. According to the company’s president, KONO Junichi, “No matter how small the market is, if there are patients in need, we should make a product for them. As a small and medium-sized enterprise (SME) that covers a niche market that big companies cannot, we would like to fill that gap in medicine.”

Kono Seisakusho focuses on developing new breakthrough products. To foster an innovation mindset, the company holds interdepartmental meetings and sets aside 30% of employees’ regular working hours for independent projects. President Kono says, “We are a manufacturer, so we have to keep making products. To that end, we need a way to challenge ourselves without worrying about failure.” Responding to his enthusiasm, employees have invented many groundbreaking products in addition to microsurgery needles, such as the world’s first suture needle with an octagonal shaft to prevent slippage, and a hemoclip for microscopic blood vessels that is made with a high-strength resin.

Another of Kono Seisakusho’s advantages is its in-house development of the materials, tools, and manufacturing equipment for its products. Making precision medical tools requires the elaborate skills of craftsmen. Although the company has fostered the professionals to satisfy that requirement, it has also been very aggressively automating its production processes. That approach maintains the high standard of the products, while sustaining the company’s manufacturing skills and knowledge so that they are passed on seamlessly to the next generation.

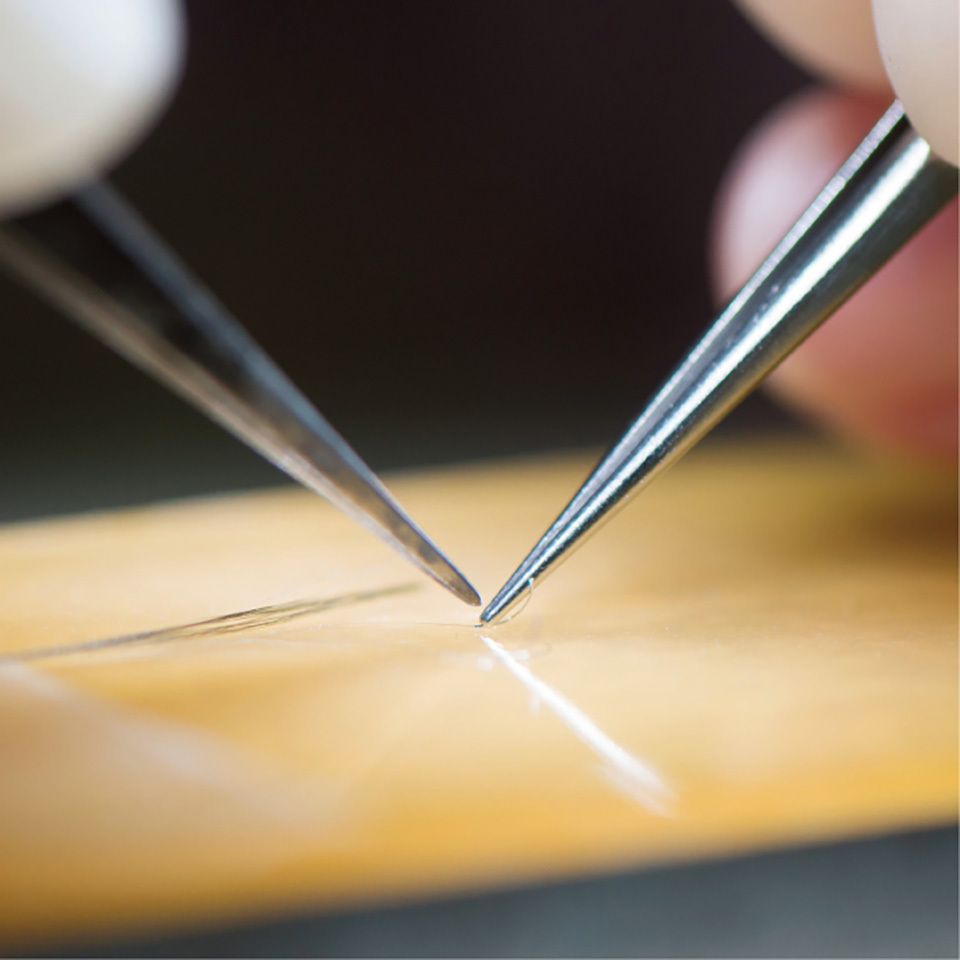

Making such small products requires precise work by hand during the production process. The photo shows a microsurgery suture needle being threaded.

Kono Seisakusho is all about high-mix, low-volume production. Numerous products are manufactured side-by-side in the company’s factory.

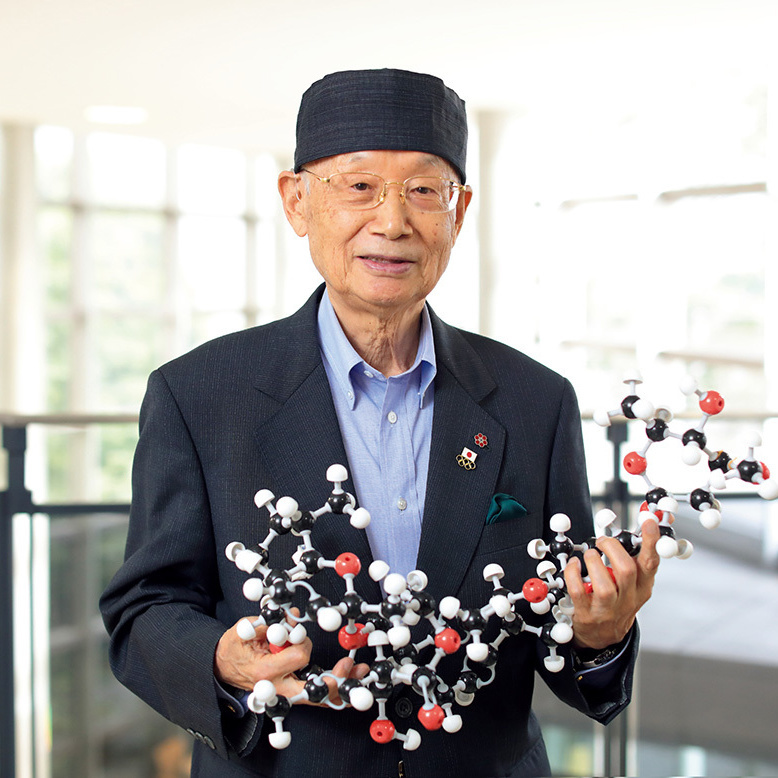

Dr. KOSHIMA Isao, professor and chief of the International Center for Lymphedema, Hiroshima University Hospital, has opened up new frontiers for microsurgery with the company’s microneedles. As he explains, “I’ve had many of my patients express their gratitude for ‘saving my life,’ but their thanks should above all else go to Kono Seisakusho’s microsurgery needles.” He emphatically adds, “To save even more lives, physicians such as myself need to do even more to tell the world about the potential of the technology.”

Kono Seisakusho has received an endless stream of inquiries from other countries about its microsurgery needles, but those products have yet to be used so often in operations around the world. The reason is that few countries have approved the company’s needles and the number of surgeons able to use them remains stagnant. That is why Kono Seisakusho is working with physicians in the field such as Dr. Koshima, while concentrating on developing the products that they truly need to save lives, as well as on raising the company’s profile among medical professionals across the globe. The powerful sense of mission—shared among engineers and physicians to improve upon medical practice—is the driving force behind innovative craftsmanship. Kono Seisakusho’s ultra-small needles, once they come into more widespread use, have a promising future saving the lives of many people worldwide.

Kono Seisakusho’s needles have earned a fine reputation among doctors beyond Japan as well. This photo was taken in Serbia at a 2019 conference of the European Federation of Societies for Microsurgery.