While the world continues to fight against the novel coronavirus pandemic, Japanese-made tents are playing a pivotal role in preventing further infections in medical settings. Taking advantage of its membrane technologies, a long-established tent manufacturer in Japan has developed a lightweight and compact negative pressure tent specifically designed for medical use, and has delivered this product around the world.

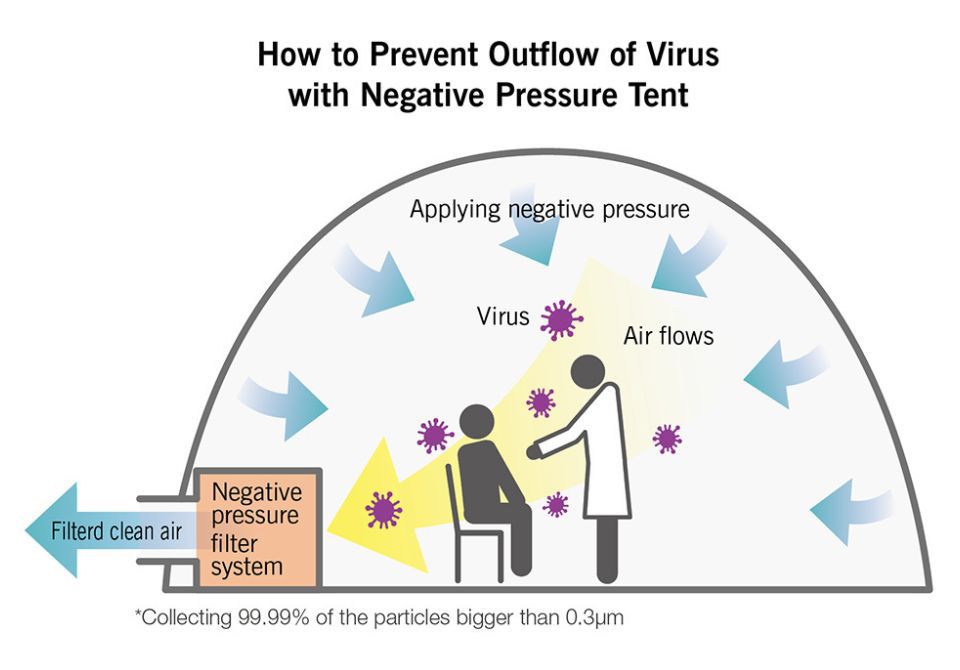

In a world where the coronavirus pandemic continues to rage on, the prevention of hospital-acquired infections is an urgent issue for the treatment of patients on medical sites. Therefore, it is extremely important to keep spaces ventilated during medical examinations and cut off from possible transmission routes. The negative pressure tent from Japan plays a pivotal role in creating such environments. Lightweight and compact, it keeps the internal pressure low and controls the flow of air to prevent viruses from spreading.

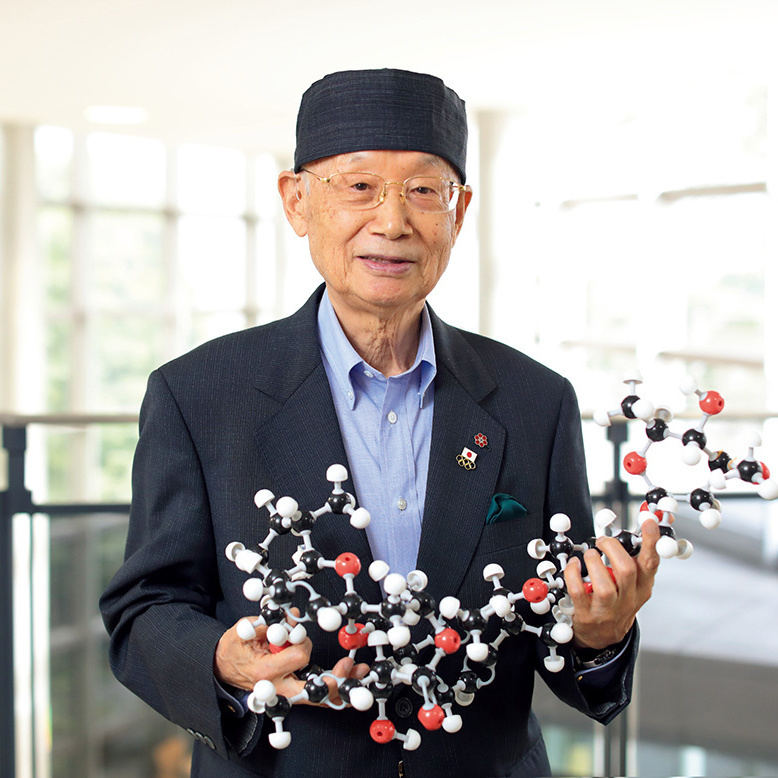

The manufacturer of the negative pressure tent is Taiyo Kogyo Corporation, founded in 1922 in Osaka. The firm, which originally made camping tents only, began to make use of its cutting and sewing techniques in the 1970s to manufacture other products and building structures from lightweight, durable membranes. By improving its technologies to respond flexibly to various demands in material development, manufacturing, and construction, the company’s products have been used in such places as the roofs of dome-shaped stadiums, facades for high-rise buildings, and other infrastructures, such as bridges.

Taiyo Kogyo has an extensive track record abroad, having worked on membrane structures for Denver International Airport in the United States and the Pompidou Center Metz in France. In 2011, the company was involved in a project in Medina, Saudi Arabia, to build large umbrellas. Taiyo Kogyo was contracted to manufacture the membrane umbrella portion, which achieved sophisticated design and a strength that can withstand the severe weather conditions in the Middle East. The membrane was developed utilizing processed fluorocarbon resin through a delicate technique.

Besides Japan, Taiyo Kogyo’s membrane technology is used in many huge structures around the world, such as Denver International Airport (the United States).

“I would like to solve all sorts of problems while communicating with people from all over the world,” says ARAKI Hidefumi, the company’s president.

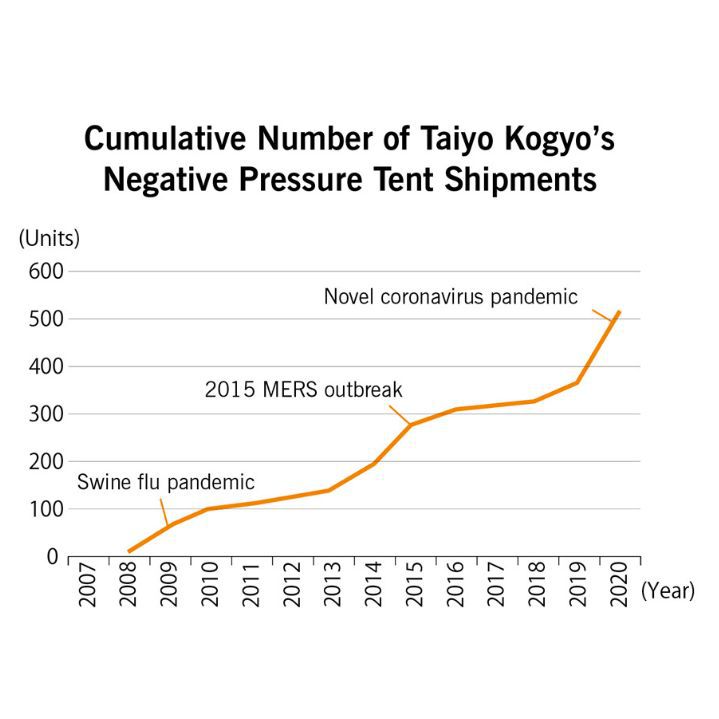

While working on large-scale structures in Japan and overseas, Taiyo Kogyo first made a compact tent in 2006 that was easy to use in disaster-affected areas. The following year, the company utilized the small tent to create a negative pressure tent for medical use. By combining the specialized air-controlling membrane with the negative pressure system, an essentially sealed space that was able to prevent viruses from escaping was created. As such, the tents have been used as temporary inspection rooms and clinics during infectious outbreaks. After being effectively used during the swine flu pandemic of 2009 and the 2015 MERS outbreak in South Korea, the tents have obtained a high reputation among doctors and other people in the medical field.

To create safer and more secure spaces, Taiyo Kogyo is currently working on developing a tent that uses ultraviolet rays to kill the virus itself. Also, a special protective suit, currently a prototype, allows infected patients in hospitals to communicate with their families face-to-face. Using membrane technology in that way, the company is able to support medical sites in their fight against COVID-19.

Taiyo Kogyo has always been looking toward the future in terms of its own product development, with the desire to “provide exceptional experiences to all sectors of the medical field through its membranes.” Versatile ideas, like the ductile membrane, might just be the driving force needed to overcome the global difficulties today.