New eco-friendly paper materials have been created through passion and time-tested technology. The papers will help people achieve Sustainable Development Goals (SDGs) and lead to reduce plastic waste.

The movement away from plastic has started to accelerate as the pollution of oceans, due to increasing plastic waste, has become a global problem. Given the urgent need to find alternatives, the development of new, environmentally friendly paper materials are attracting attention.

A paper material created from a completely novel concept promoted by a group of Japanese entrepreneurs, is now available: banana paper, made from discarded banana stems. The stems, which would otherwise be thrown away, are purchased from organic banana farmers in Zambia, Africa, then, processed for their fiber in a local factory, after which they are made into paper products in Japan and England.

Leading the project is EKBERG Satoko. Determined to find a way to generate sustainable employment in an impoverished region of Zambia, she eventually arrived upon the idea of making paper from banana stems, which are normally discarded in large quantities. And since traditional Japanese papermaking has used non-wood sources of pulp from time immemorial, developers drew the idea from that fund of skills and wisdom. Ekberg also says the cooperation of many other entities has been indispensable, including paper manufacturers, printing companies, and experts on the environment. “By cooperating across institutional boundaries, we have created a ‘paper beyond paper’ that will not only protect people’s lives, but also protect forests and wild animals from poaching caused by poverty.”

Having obtained the approval of the World Fair Trade Organization (WFTO), banana paper has been introduced as a packaging material for a global manufacturer of cosmetics products, and is also utilized in various other innovative ways, such as in containers and clothes hangers. As efforts to achieve SDGs inspire new activity at the enterprise level, requests have dramatically increased for the co-development of products.

The production of banana paper creates jobs in impoverished regions, enabling some team members to send their children to college.

EKBERG Satoko (right) explains how the project was started. Maintaining a firm determination to continue moving forward, she is focused on further developing banana paper products.

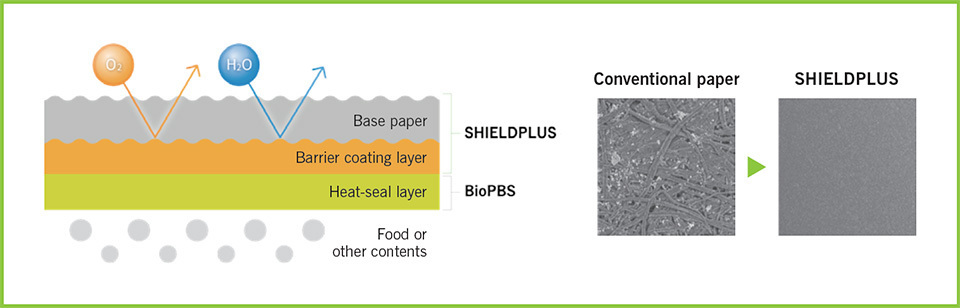

At the same time, attempts are also moving forward to enhance conventional paper with new capabilities. SHIELDPLUS, a new kind of paper developed by Nippon Paper Industries Co., Ltd., has the property of being impermeable to oxygen, vapor, and odors. In general, high hopes have been placed on paper as a possible replacement for plastic since it is a biodegradable, renewable resource. However, its high permeability makes it difficult to be used as a packaging material for fresh food and similar products. To overcome that problem, Nippon Paper Industries has applied its water-based coating technology—normally used for treating magazine covers and other special papers—to develop a unique barrier layer over paper, which produced SHIELDPLUS. Its low oxygen transmission rate gives it barrier properties comparable to those of plastic barrier films—now in widely used for wrapping foods, pharmaceuticals, and similar products—making it a truly innovative paper material.

Expanding beyond its original use as a food-packaging material, SHIELDPLUS is now being introduced into more fields. Because the product is impermeable to odors, Nippon Paper Industries continues to broaden its range of applications.

Even when SHIELDPLUS is used as a food package, a thin plastic film is still needed to seal the inside so as to protect the quality of the contents. For that, Nippon Paper Industries, in a new deal, has utilized BioPBS, a biodegradable resin developed by Mitsubishi Chemical Corporation. The two companies have co-developed a new recyclable packaging material using BioPBS as a heat-seal layer. Each component, made from recyclable materials, is thus biodegradable. Together, they effectively prevent the deterioration of the package’s contents.

Amidst rising consciousness of the need to reduce plastic consumption, a growing number of businesses have introduced SHIELDPLUS packaging materials. With a deluge of inquiries from overseas, Nippon Paper Industries looks forward to developing cooperative projects with a variety of companies, while continuing to explore new possibilities for paper.

Paper materials may offer even more possibilities that are still unseen. We may thereby discover other solutions to global issues through cooperation and the sharing of ideas and technology.

A paper substrate, made totally from wood material, is given a layer of coating that features proprietary technology, forming the SHIELDPLUS barrier material. With BioPBS applied as a sealant, the paper can then be used as a recyclable packaging material.