What comes to mind when you hear the word “concrete”? Most of us probably think of it as something thick and heavy—but ten years from now, we may view it quite differently. A Japanese startup has developed concrete that is thin, lightweight, robust, and conducive to flexibility in building design. The company’s pioneering technology is already reshaping our image of concrete.

Many buildings and other structures we see today are made with reinforced concrete. Concrete is highly resistant to compressive forces but has low tensile strength against pulling forces, which is why reinforced concrete, with steel bars inserted to increase its strength, has been used for many years. Despite its greater strength, however, unresolved issues remain with reinforced concrete as well.

Cement, the main component of concrete, makes the concrete highly alkaline. When atmospheric CO₂ penetrates concrete and neutralizes its alkalinity, rainwater and oxygen can make the reinforcing steel bars corrode and expand, causing the concrete to crack. To prevent this, the embedded steel rebar must be protected from exposure to the elements by making the concrete thick enough to shield it. This countermeasure, however, ends up making reinforced concrete thick and heavy.

HPC Okinawa Co., Ltd. has solved this problem with its innovative Hybrid Prestressed Concrete (HPC) technology. Instead of conventional rebar, carbon wires made of highly tensile twisted carbon fibers are embedded in the concrete. This eliminates concerns about rust and reduces the concrete’s thickness to as little as 38 mm, all while maintaining strength equivalent to conventional concrete.

The unique technical feature of HPC is its combined use of two different types of prestressing process, as the word “hybrid” suggests.

The first process is mechanical prestressing. During production, the wires are pre-stretched as one might stretch rubber, after which concrete is poured over them. When the stretching is halted after the concrete has hardened, the pre-stretched wires exert force as they try to return to their original state, causing the concrete to contract with them. This reaction compresses the entire slab of concrete, increasing its density and strength.

The second process is chemical prestressing. An expansive agent is added to the concrete, where it reacts with water to form crystals of calcium hydroxide. This reaction causes the concrete to attempt to expand, but its expansion is restrained by the effect of the mechanical prestressing, resulting in a further increase in its density and strength.

Mixing polypropylene fibers into the cement, moreover, enhances resistance to cracking. Combining this with the two forms of prestressing yields concrete that is not simply thin and lightweight but also extremely durable and robust.

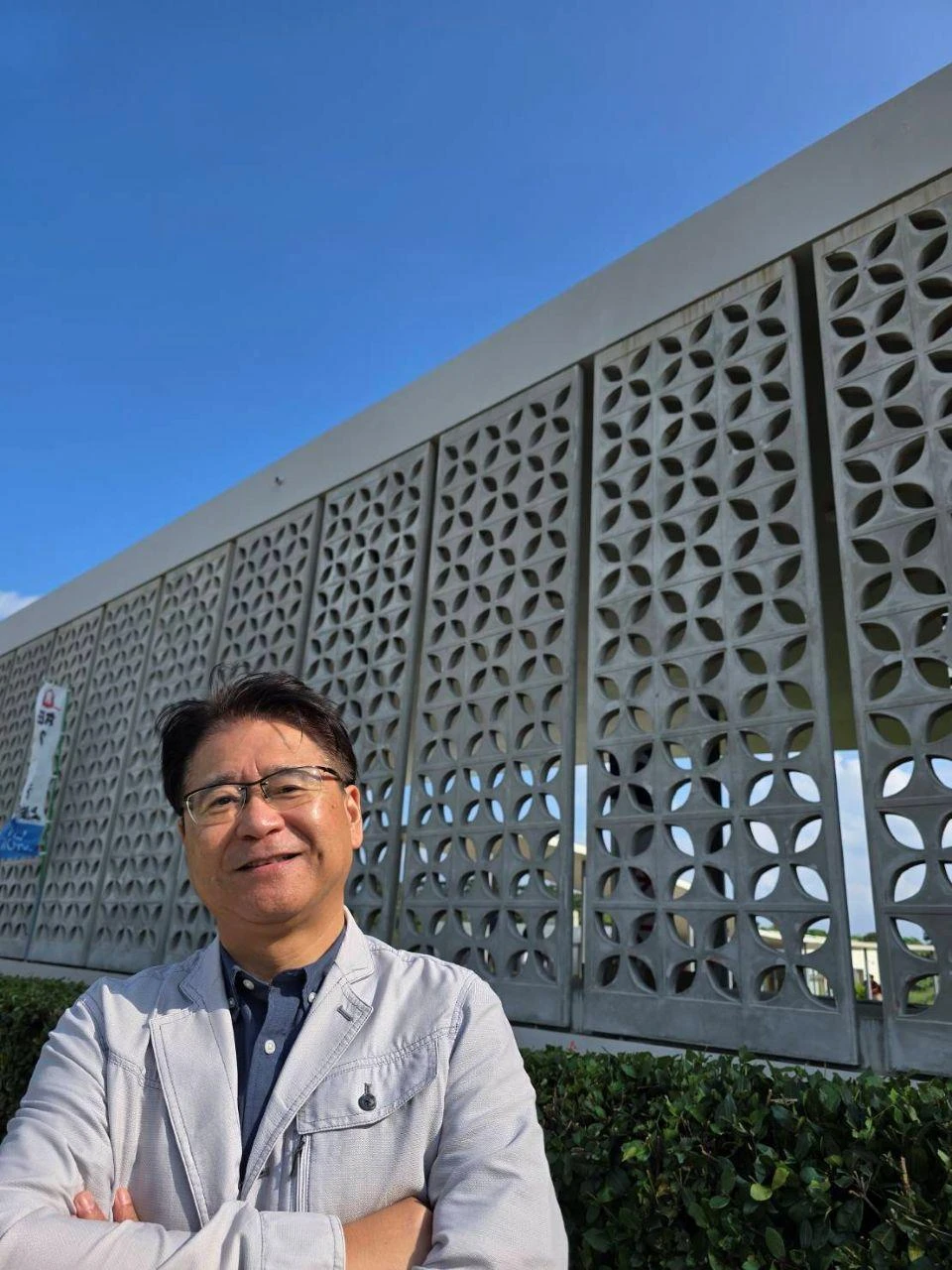

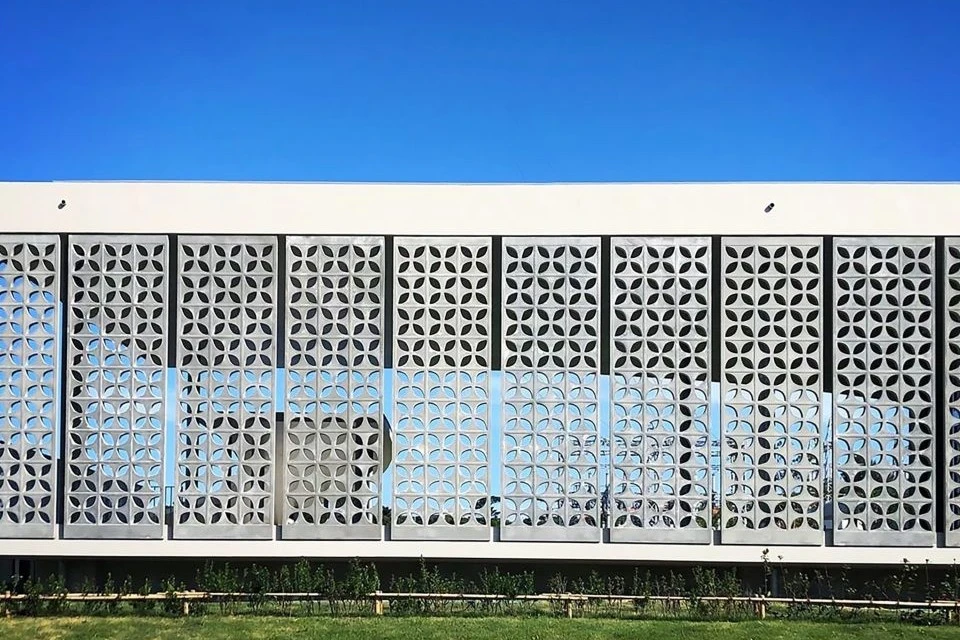

One day, AHAGON Masaki, president of HPC Okinawa and the developer of HPC, received a request from an architect that proved to be the impetus for development of the technology. “In Okinawa, we have building materials known as ‘hana [flower] blocks’—concrete blocks with holes cut out in patterns. I was asked to produce something that would allow for the same cutout design style as these blocks, but on a curved surface. That was a pretty outrageous demand, but it turned out to be the motivation I needed.” Ahagon searched the internet for building materials worldwide that would fulfill the architect’s request, but found no thin materials that could be perforated like that as well as used on curved surfaces. He decided that if such a material did not exist, he would produce it himself—and so began his development of a new kind of concrete.

After repeated trial and error, Ahagon finally produced a panel using HPC technology. Its properties of thinness, light weight, and a robust structure that permits the cutting of holes added significantly to the value of the material. In 2015, he obtained a domestic patent in Japan for this new type of prestressed concrete, followed by patents in the United States, Europe, and elsewhere. Today, HPC is used in public facilities in Okinawa Prefecture as well as commercial facilities in the Tokyo metropolitan area and the Kansai region.

Naha Cultural Arts Theater NAHArt in Naha, Okinawa Prefecture.

Currently, HPC technology is moving on to a “second generation” phase of application as a key tool in achieving a decarbonized, low-carbon society. HPC panels on the facade of a pavilion at Expo 2025 Osaka, Kansai, Japan, were made with 100% seawater instead of freshwater to mix the concrete. Ahagon explains that using seawater does not simply help island countries with scarce freshwater resources; the salt from the seawater in the HPC panels reacts with atmospheric CO₂ to form a structure similar to rock salt that increases the density of the concrete, making it even stronger.

Concrete manufacture typically emits large amounts of CO₂. However, HPC panels can utilize, as one of their materials, the calcium carbonate produced from the chemical reaction of CO₂ exhaust gas with the calcium in the raw material of the concrete. This contributes to reducing the lifetime CO₂ emissions of concrete products and achieving a net negative carbon footprint for the material.

HPC Okinawa is also conducting demonstration experiments with reef plates made of HPC and sunk to the seabed. These serve as substrates for the growth of algae and seagrass, with the aim of restoring and nurturing seagrass beds ravaged by sea urchin grazing. Seagrass beds play a vital role in blue carbon ecosystems by absorbing and storing CO₂ in the sea, so these HPC reef plates can contribute to marine ecosystem restoration as well as to global warming countermeasures.

About future prospects, Ahagon says: “HPC is a concrete-based solution that can continue to evolve by catering to a variety of needs, with no limits in sight. Moreover, Japan leads the world in the carbon wire technology that is essential to HPC. I hope that this pioneering material, born right here in Okinawa, will go on to help solve problems all over the world.”

About future prospects, Ahagon says: “HPC is a concrete-based solution that can continue to evolve by catering to a variety of needs, with no limits in sight. Moreover, Japan leads the world in the carbon wire technology that is essential to HPC. I hope that this pioneering material, born right here in Okinawa, will go on to help solve problems all over the world.”