Around the world, millions of children fall victim to infectious diseases like malaria and measles and die before they reach the age of five. While vaccines are effective in preventing those diseases, many parts of developing countries suffer from poor transportation infrastructure, with limited transport options that make it difficult to deliver vaccines under proper low-temperature conditions. A Japanese home appliance manufacturer offers a solution to this problem with a unique breakthrough in cooling technology.

A vaccine freezer equipped with a Free Piston Stirling Cooler (FPSC) unit. With external dimensions of 695 mm (W) x 350 mm (D) x 460 mm (H), and a capacity of 25 liters, the freezer is about the same size as a standard cooler box.

Over 4.8 million children worldwide die every year before they reach age five. The leading causes of their mortality are pneumonia, diarrhea, and malaria. Vaccines are one effective means of protecting them from infectious diseases such as malaria and measles. Many children’s lives can be saved if they have access to vaccines and vaccination facilities, but the vaccines have short shelf lives and need to be stored within a specific temperature range. That makes it essential to have a low-temperature storage and transport system, known as a cold chain, in place from source to destination.

Vaccines from international organizations like UNICEF are generally transported in vehicles equipped with cold storage to local health centers, where they are transferred to transport boxes with ice packs for delivery to hospitals. However, many areas in developing countries suffer from poor transportation infrastructure with limited transport options. Consequently, vaccines are often transported in ordinary automobiles or motorcycles without cold storage, and in some cases are carried by hand for hours without adequate cooling equipment at temperatures that exceed the vaccine’s optimal range.

Twinbird Corporation, a mid-sized Japanese home appliance manufacturer, offers a pioneering solution to this problem with its proprietary cooling technology. The Free Piston Stirling Cooler (FPSC) enables precise temperature control to within 1°C, even at extremely low temperatures of minus tens of degrees. In contrast to the compressor-based cooling systems used in household refrigerators, freezers equipped with FPSC technology are compact, resistant to vibration, and easy to transport, allowing vaccines to be delivered without any adverse effects even under the harsh conditions found in many developing countries. Moreover, the unit can be powered from an automobile’s auxiliary power outlet, offering the advantage of use even in areas without electricity.

Twinbird Corporation has its headquarters in a rural setting in Tsubame, a city in central Niigata Prefecture.

FPSC is a cooling technology based on the principle of the Stirling cycle, utilizing the fact that the temperature of a gas rises when it is compressed and falls when it expands. The helium gas refrigerant in the container is cooled down through repeated compression and expansion by two pistons moving alternately up and down inside a cylinder. This system offers the advantage of being smaller and lighter than cooling units that use compressors. However, the manufacturer had to overcome some daunting hurdles to achieve mass production of its FPSC unit.

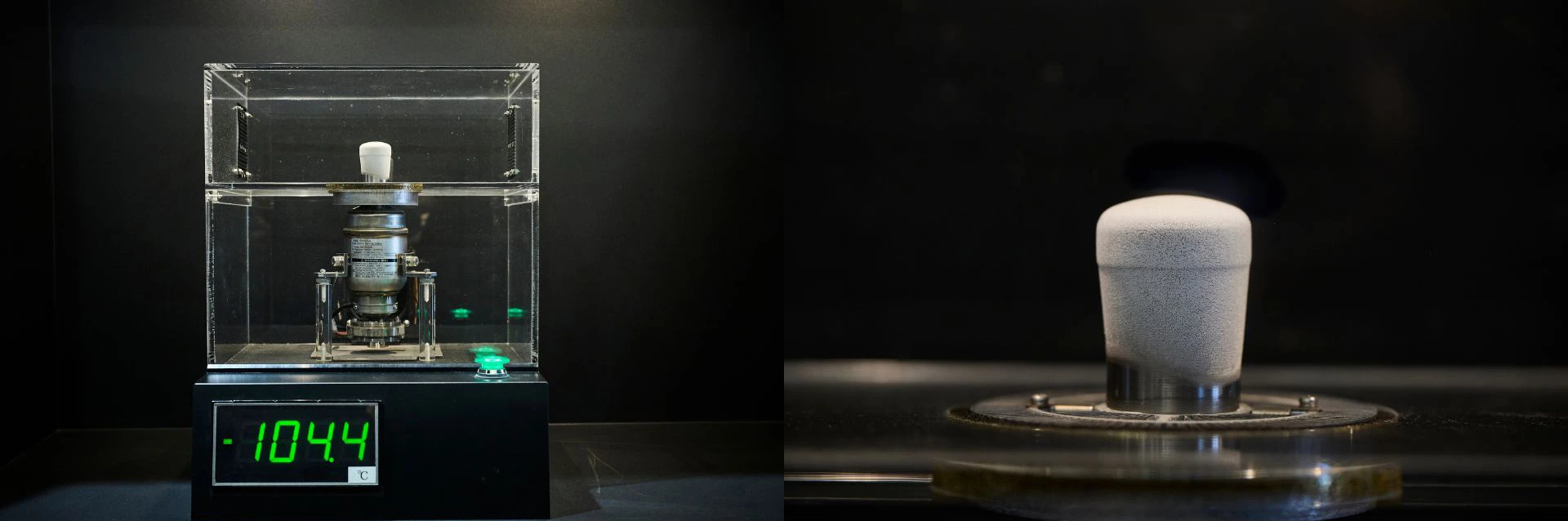

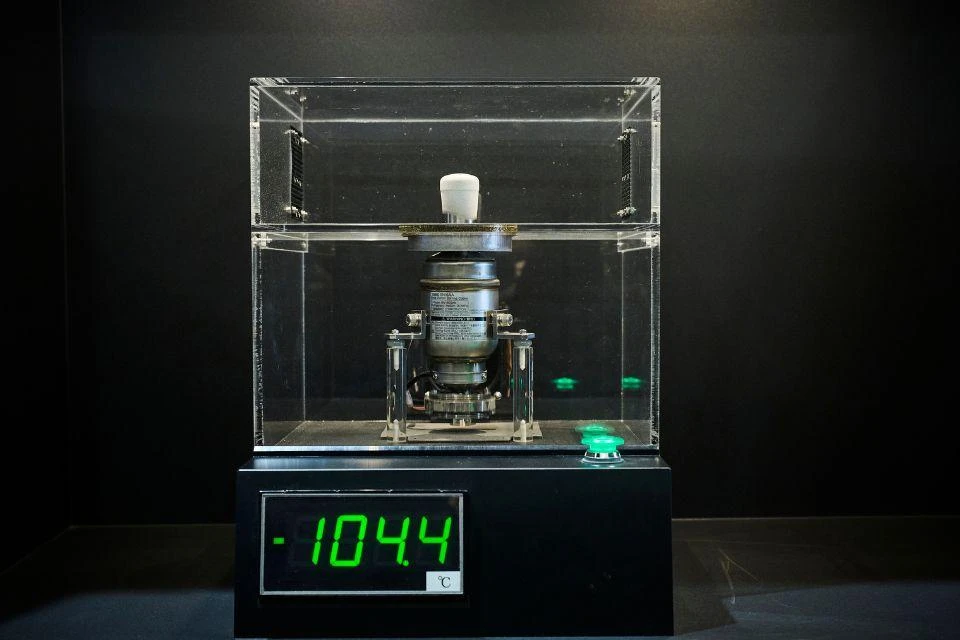

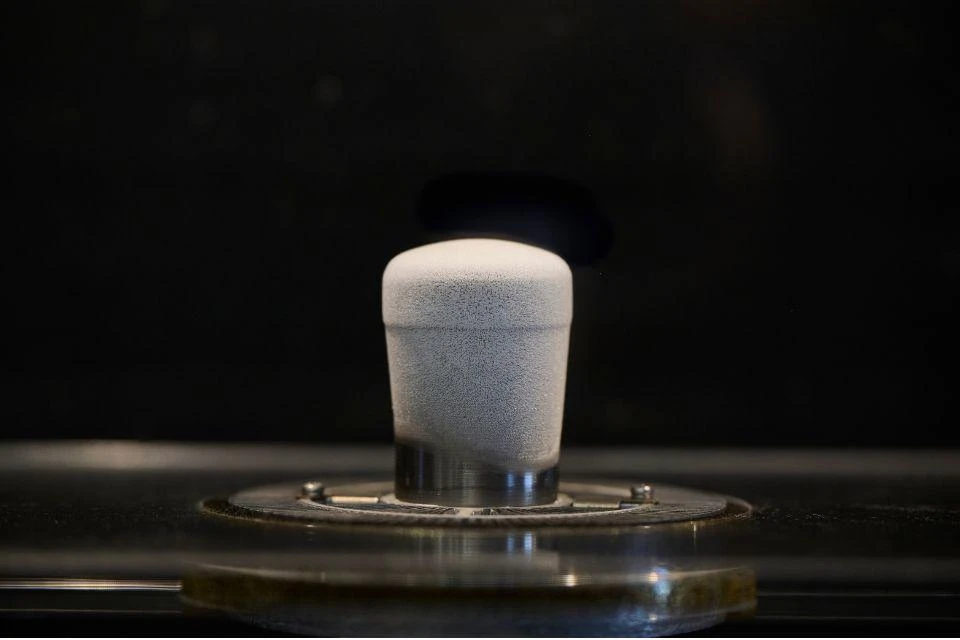

Left: Demonstration model of the FPSC unit. Right: When switched on, it can cool down to -100°C in about five minutes, with frost rapidly forming on the heat absorption element.

Demonstration model of the FPSC unit.

When switched on, it can cool down to -100°C in about five minutes, with frost rapidly forming on the heat absorption element.

One factor that made mass production difficult was the high precision required for this technology. The FPSC unit is composed of about 150 different parts, and the clearance between the cylinder and pistons that form the engine, which is the core of the technology, can only be 0.01 mm—ten times the precision of an automobile engine.

“This technology could only be developed because we are from Tsubame-Sanjo,” proudly declares NOMIZU Shigeaki, President and CEO of Twinbird Corporation. The Tsubame-Sanjo region of Niigata Prefecture, where Twinbird has its headquarters, has been a metalworking center for over 400 years, and the FPSC was developed utilizing the metalworking knowhow of some 30 local companies.

An engineer inspects an FPSC cylinder. Twinbird’s unique knowhow and the high-level skills of its engineers make precision at the micron level possible.

During the Covid-19 pandemic, the company expanded its production tenfold from 300 to 3,000 units per month at the request of the Ministry of Health, Labour and Welfare, supplying a total of 12,000 units* for the transport of Moderna vaccines. As part of the “Last One Mile Support” initiative conducted by the Ministry of Foreign Affairs and Japan International Cooperation Agency (JICA) to deliver Covid-19 and other vaccines to vaccination centers overseas, units were also provided at no cost in such places as Timor-Leste, Mozambique, Senegal, Mongolia, and Palestine. They are still being used today to transport vaccines for polio and other diseases.

An FPSC-equipped vaccine freezer** (right) in use at a vaccination center in Timor-Leste.

In October 2024, Twinbird Corporation received the Performance, Quality and Safety (PQS) certification for medical equipment established by the World Health Organization (WHO).*** Following the exhibition of the company’s FPSC-equipped freezer at the Tokyo International Conference on African Development (TICAD) held in Yokohama in August 2025, an even lower-temperature model was exhibited in November that year at MEDICA, the world’s largest international medical equipment expo, in Düsseldorf, Germany.

About future prospects, President Nomizu says: “Achieving PQS certification makes it easier for us to approach international organizations and global funds. We aim to deliver vaccines to many more developing countries and contribute to the reduction of child mortality. Currently, we’re making a prototype of a freezer capable of even lower temperatures, down to -80°C. Going forward, we would like to expand into new fields, such as the transport of cutting-edge pharmaceutical products and biological samples.”

NOMIZU Shigeaki, President and CEO of Twinbird Corporation.

* SC-DF25WL (Temperature setting: +10°C to -40°C, portable)

** SC-BV25 (Temperature setting: +4°C, portable)

*** SC-DF25P (Temperature setting: -20°C, stationary; WHO PQS-certified)