In many parts of the world facing low agricultural productivity and food shortages, technological factors behind these problems are compounded by environmental factors such as weather and soil quality. Now, a company in Japan has developed a revolutionary plant activator that rejuvenates the inherent capabilities of the soil to improve harvest output. Inexpensive and easy to produce on-site, this invention has the potential to open up new possibilities in sustainable agriculture worldwide. The product’s name reflects its place of origin: TOKYO8.

Spraying the plant activator TOKYO8 in a cabbage patch in Zambia.

TOKYO8 is a plant activation compound that utilizes the power of microbes. Unlike compost or fertilizer, it works by rapidly breaking down organic matter in the ground to invigorate the soil and increase crop yields. Because different microbes are active in different environmental conditions, TOKYO8 is also notable for its effectiveness in a diverse range of soils around the world.

TOKYO8 was developed by Tokyo-based Taiyo Yuka Co., Ltd. The company’s main business is waste treatment, using microbial biolysis to render the thick sludge from urban drainage harmless.

Culture tanks at the TOKYO8 plant in Tokyo.

The Tokyo metropolitan area is one of the world’s largest by population. A vast range of foodstuffs from around the globe is constantly being consumed by that population, and the resulting waste products vary in composition from day to day. To process that ever-changing sludge in a speedy and stable fashion, treatment plants need to use the right bacteria for the waste products of the day. Consequently, Taiyo Yuka has been researching bacteria since it entered the business in 1989. One result of that research is a “secret recipe” for a combination of 1,500 types of bacteria that is effective on sludge of any composition.

Culture tanks at the TOKYO8 plant in Tokyo.

“Given what these bacteria can do, it seemed like a waste to use them solely to process sludge,” says Taiyo Yuka CEO ISHIDA Taihei. When the company began searching for ways to commercialize the formula for other uses, agricultural applications emerged as one possibility. After that, joint research was conducted with institutions like the University of Tsukuba and Saitama University to identify bacteria with properties beneficial to agriculture, and TOKYO8 was born.

TOKYO8 in concentrated form. This liquid is diluted and then sprayed on soil and leaves.

TOKYO8 concentrate is diluted by a factor of 10 to 100 and then sprayed on soil or leaves, where it begins to take effect immediately. By efficiently breaking down organic matter in the soil, the bacteria in TOKYO8 join soil particles together into lumps. More lumps mean more gaps within the soil, making it “fluffier.”

This effect makes it easier for roots to grow in the soil, improves drainage and water retention, and conserves the soil’s microbiodiversity. This, in turn, allows plants to absorb more nutrients, helping them grow in a healthy state. Experiments found that soil where TOKYO8 was used produced 50% more harvestable crops than soil where it was not, and that the harvested plants and vegetables were up to twice as large.

The sheer versatility of TOKYO8 is also noteworthy. Because it was developed to process the vast diversity of sludge of the Tokyo metropolitan area, its 1,500 different strains of bacteria can be effective in soils all over the world.

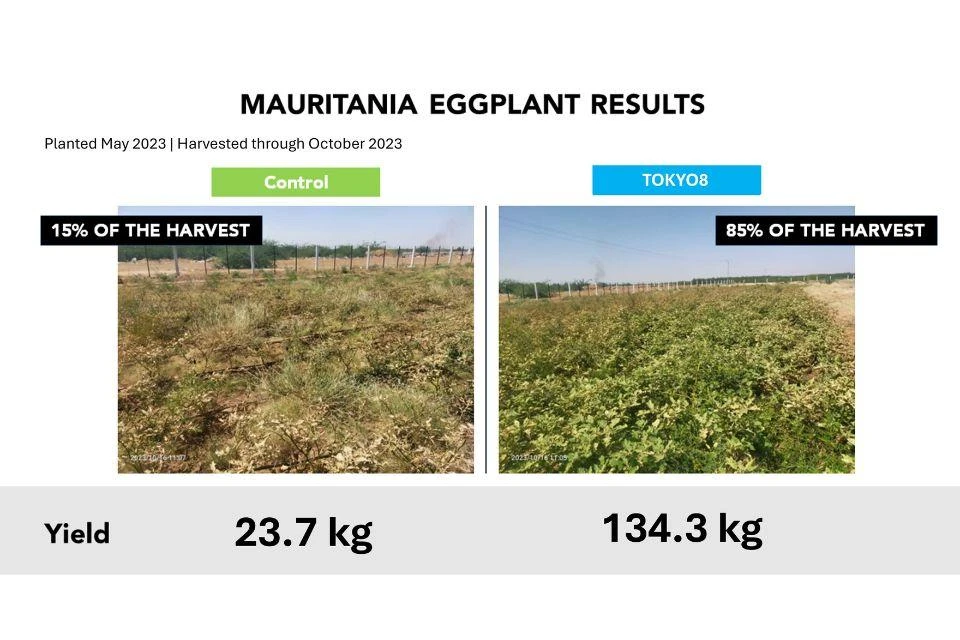

A cultivation test in Mauritania. The eggplant field on the left used only compost, while the field on the right used compost and TOKYO8, with both fields tiled over the same period. Applying TOKYO8 resulted in a dramatic increase in harvested output.

Currently, TOKYO8GLOBAL Co., Ltd., part of the same corporate group as Taiyo Yuka, exports the concentrate and cultures TOKYO8 locally for distribution. Local culturing lowers the cost of introducing TOKYO8 in developing countries.

“Many farmers in Asia and Africa make a living from small plots of land,” says Ishida. “We hope to broaden our business model by signing franchising agreements with them, so that they can manufacture enough TOKYO8 for use on their own fields, plus a surplus that they can sell to supplement their income.”

Local manufacturing involves preparing a simple apparatus with four 1,000-liter containers connected by pipes, then adding TOKYO8 concentrate to local waste such as cow manure and culturing the result. Some 3,000 liters of ready-to-use TOKYO8 can be produced monthly from just 10 liters of concentrate—a 300-fold increase.

This apparatus in Lilongwe, Malawi, began manufacturing TOKYO8 in May 2025. The rearmost tank contains finished TOKYO8 ready for application.

“A hectare of farmland needs ten liters of TOKYO8 per month,” says Ishida. “If you have 3,000 liters, you can cover 300 hectares, so a medium-sized farm in Africa can handle all its needs with one of these units.”

Because TOKYO8 can improve soil at minimal cost, facilitating local production of food for local consumption, it could also contribute to the resolution of such problems as poverty and famine. One TOKYO8 franchise partner in Liberia has already initiated a school lunch program in order to improve child nutrition, using locally grown vegetables produced with the help of TOKYO8.

“We’re currently working toward expanding into Indonesia, with two local companies now being launched,” says Ishida. “We look forward to substantively expanding our business model in Africa and Southeast Asia.”

Born in the unique environment of the international metropolis of Tokyo, in the very near future, TOKYO8 could revitalize agriculture and contribute to sustainable food production around the world.

ISHIDA Taihei, CEO of Taiyo Yuka Co., Ltd.