Wind power’s promise as a major source of renewable energy has driven the rapid deployment of wind farms around the world. But inspecting and repairing wind turbines is dangerous and precarious work, and securing personnel and covering costs is expected to grow more challenging as turbines grow in size and number. One Japanese startup is combining robotics and AI to offer an innovative solution to this problem.

Wind power promises to be a major source of renewable electricity, and wind farms are being deployed rapidly around the globe. Analysts predict that by 2030, installed wind power capacity will increase by 300% onshore and 1,000% offshore from 2020 levels.

As wind turbines grow in size and number, however, new challenges have emerged. Even minor damage to turbine blades can reduce operational efficiency or lead to major accidents, and constant exposure to the elements inevitably causes wear and tear, so regular inspections and repairs are essential. Currently performed by human technicians, this maintenance is dangerous work performed at great heights using ropes and cranes, and personnel shortages and cost increases are both concerns for operating businesses.

To resolve these issues, LEBO ROBOTICS Inc., a startup founded in 2018, developed the world’s first wind turbine maintenance robots. Robotics-based solutions for inspecting and repairing wind turbines are also under development in Europe, a leading region in wind power adoption, but few of these projects have been successfully commercialized.

According to HAMAMURA Keitaro, CEO of LEBO ROBOTICS, the damage that accumulates on turbine blades over three to five years reduces generation capacity by 3 to 10%.

“Particularly in Japan, the United States, and Europe, where personnel costs are high, maintenance staffing and costs are a challenge,” says Hamamura. “Using robots for maintenance enables a swifter response to the causes of generation capacity loss, keeping the equipment in an optimal state and delivering great benefits to the operating businesses.”

LEBO ROBOTICS offers three distinct services. The first is blade inspection and maintenance using its own robots. The second is AI analysis of images taken by ground-based cameras and drones. The third is development and deployment of chemical products like paint and adhesives. The company combines these services to offer optimal maintenance plans and serve as a one-stop shop for post-installation wind turbine maintenance.

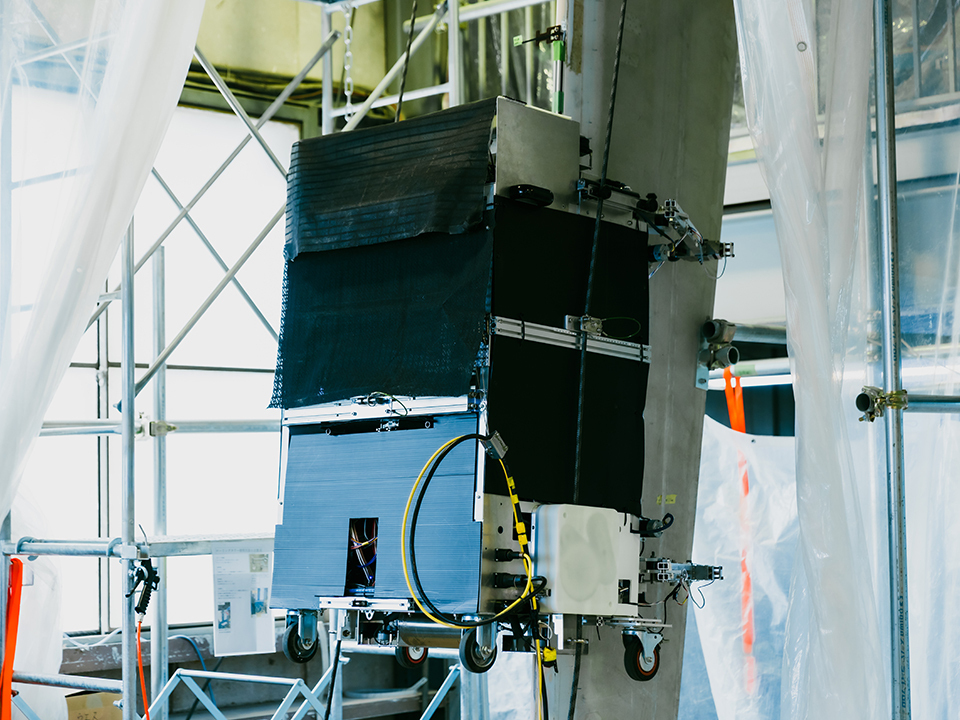

Inspection robots controlled from below move across the blades and confirm electrical connectivity, a countermeasure against lightning strikes.

Inspection, the first stage of maintenance work, involves AI analysis of images taken from ground-based high-resolution cameras equipped with telephoto lenses, or aerial photography performed using drones. Damage is evaluated on a four-level scale. LEBO ROBOTICS also deploys an inspection robot developed in-house to check for any abnormalities in each turbine’s ability to act as a lightning conductor.

Inspection robots controlled from below move across the blades and confirm electrical connectivity, a countermeasure against lightning strikes.

If damage requiring repair is found, a repair robot equipped with a scanner and camera is deployed. Captured images are converted to data, and information about the location, type, and level of each instance of damage is accumulated.

“Damage to the blade surface is converted into 3D data at a resolution of 0.1 millimeter,” says Hamamura. “Analyzing this data renders patterns visible: ‘Damage like this occurs over such-and-such a period in this locale,’ or ‘This turbine model from that manufacturer has these tendencies.’”

The entire repair process—scraping, adding putty, polishing, and adding the top coat of paint—can be performed while measuring and analyzing irregularities in the blade’s surface at 0.1 millimeter resolution. Compared to repair work performed by hand, polishing time is cut in half and painting time reduced by two-thirds. At present, the work is performed by a ground-based operator using remote control, but within a few years, LEBO ROBOTICS expects to offer fully autonomous robots. A more long-term goal is the development of a single robot that can perform both inspection and maintenance.

An operator uses remote control to guide a repair robot as it fixes damage to a blade.

“As well as technological innovation in robotics, of course, we eventually hope to develop predictive maintenance by using the data we accumulate,” says Hamamura. “By constructing a digital twin [real-time one-to-one digital simulation based on real-world information] for each turbine and providing optimal maintenance plans, we can reduce costs while maximizing operational efficiency. That should further accelerate the adoption of wind power worldwide.”

LEBO ROBOTICS offers a vision of “a world in which people can lead comfortable and happy lives while preserving the environment.” It continues to make strides in its contribution toward achieving that world.

HAMAMURA Keitaro, CEO of LEBO ROBOTICS Inc.