Early-stage lung cancer is often difficult to detect with X-rays and CT scans. Since patients themselves are frequently unaware of their condition, this form of cancer is discovered at an advanced stage in many cases. Now, a Japanese research team is working on a way to “breath-test” for early detection of lung cancer, measuring its presence via the analysis of traces in the breath.

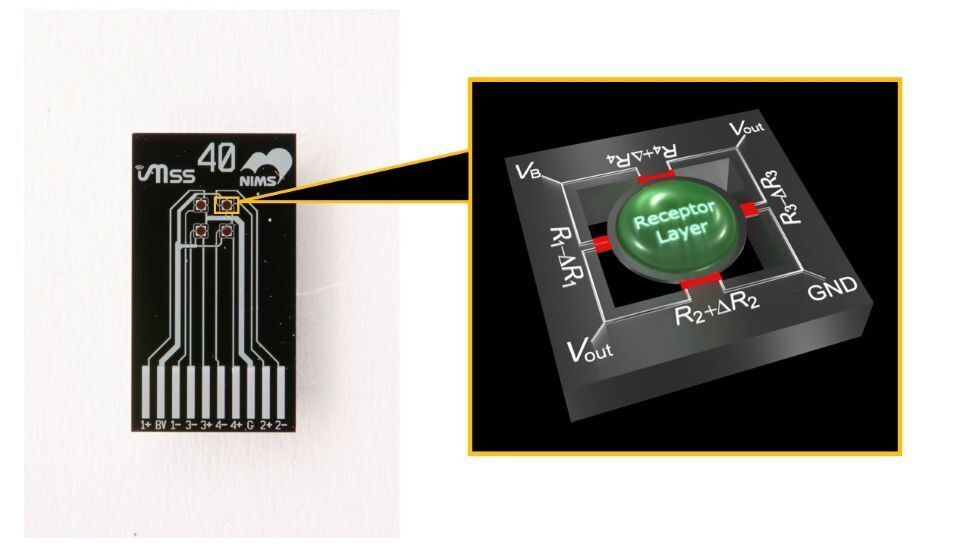

The odor-detecting Membrane-type Surface stress Sensor (MSS) chip developed by a team led by the National Institute for Materials Science (NIMS). The chip is 10 mm long and 5.5 mm across and has four detection units, each just 0.3 mm in diameter.

According to a 2022 World Health Organization report, lung cancer is the deadliest cancer in the world. At present, the main methods for detecting lung cancer are X-rays and CT scans, but early-stage lung cancer is difficult to identify via X-rays, and CT scans have their own issues, such as radiation exposure and high costs. This has generated great interest in a new project to devise a means of detecting lung cancer via odors on the breath. Led by the University of Tsukuba Hospital in collaboration with the National Institute for Materials Science (NIMS) and Ibaraki Prefectural Central Hospital, the project uses Membrane-type Surface stress Sensor (MSS) technology, whose development was headed by NIMS.

Every human exhalation is composed of more than a thousand different gases. Cancer alters that composition, and there are reports of dogs detecting cancer in patients by smell alone. This phenomenon inspired the team to launch a project to reproduce the olfactory sense through technology.

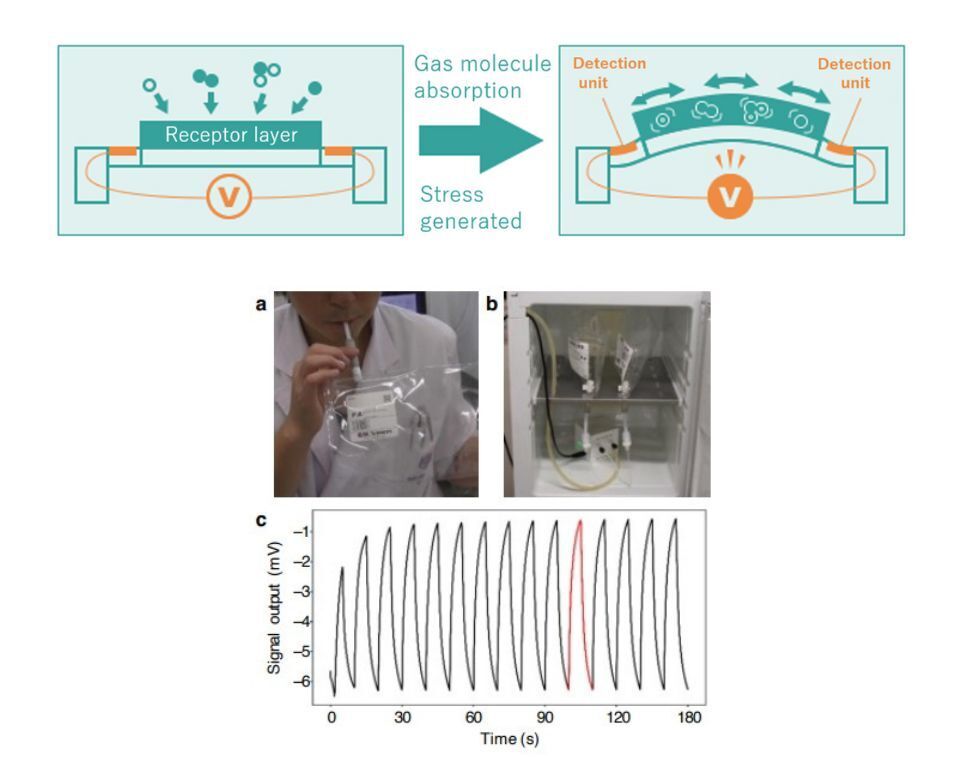

YOSHIKAWA Genki, Group Leader of NIMS’s Olfactory Sensors Group, showed us the result of the Group’s MSS development project: a chip 10 mm long and 5.5 mm across. The MSS is a nanomechanical sensor—a kind of miniaturized sensor used to detect trace components in gases and liquids. An MSS chip houses several thin membranes, known as “sensitive membranes,” that detect specific substances. Each of these membranes is around 0.3 mm in diameter and 1 μm thick. When the membrane absorbs an odor molecule, it flexes minutely as stress is generated on its surface. Detectors capable of sensing that stress as electrical resistance are embedded in the four beams supporting each membrane to detect the change as a signal. Using a structure with four points of support makes the MSS around 100 times more sensitive than previous nanomechanical sensors of this type.

The team also developed an AI application by using the different responses to various exhalation components as training data to construct a discriminative model. Applying this model made it possible to evaluate whether the sensor’s response pattern was characteristic of cancer or not.

The structure of the MSS and its surrounding circuitry. The thin membrane at the center is supported by four beams for efficient measurement of surface stress.

When the University of Tsukuba Hospital used this MSS technology to test the breath of 66 patients before and after lung cancer surgery, “it was able to distinguish between pre- and post-surgery exhalations with over 80% precision,” says Yoshikawa. While these results are only at the trial stage, with many kinds of verification still required, they suggest the possibility of a new screening method for early detection of lung cancer.

Even reaching this point was no easy process. For example, collecting breath samples is complicated by the fact that the air at the beginning of an exhalation differs in its components from air coming from deep within the lungs. “When should we take and measure the breath sample? What material should be used for the collection bag? Even the most minuscule aspects affect the results,” says Yoshikawa. Differences between individuals also have a significant impact, so for these early trials, cooperation was requested of patients undergoing surgery for lung cancer in order to measure their breath before and after the procedure. This made it possible to obtain highly reliable data that minimized the effect of patient differences in age, sex, smoking history, pulmonary and renal function, and so on.

Stress is generated on the MSS’s sensitive membrane and the sensor’s response. When a gas molecule is absorbed by the membrane at the center of the MSS, the resulting stress is detected electrically by the detection unit.

The research team is currently focusing its efforts on identifying biomarkers unique to cancer. As of July 2025, they had yet to discover a chemical substance that indicates the presence of cancer with certainty, which Yoshikawa sees as the greatest challenge. No matter how precisely the technology can distinguish pre- and post-surgery cancer patients by breath alone, thereby demonstrating that cancer changes the composition of the breath, this does not guarantee that the technology can discern the presence of cancer. “We hope to identify biomarkers within five years, prove that these components can be distinguished with high sensitivity by the MSS, and put the technology to practical use within ten years,” says Yoshikawa.

YOSHIKAWA Genki, Group Leader, Olfactory Sensors Group (right), and IMAMURA Gaku, Senior Researcher, Electrochemical Nano-bio Group (left), both part of the Biomaterials Field, Research Center for Macromolecules and Biomaterials. Yoshikawa and Imamura are working on social applications of MSS technology at Qception Corporation, a NIMS-launched startup.

Since the MSS chip is so small, it could one day be installed on a device as compact and portable as a cellphone, making “breath tests” for cancer easy. With that goal in mind, this research team continues to work on early detection methods that promise to reduce the high mortality rate of lung cancer.