The world’s population is predicted to increase from 8.2 billion in 2025 to 9.7 billion by 2050, raising concerns about food shortages, particularly of protein supplies. With aquaculture attracting notice as a way to meet global protein demand while protecting marine resources, a Japanese startup company aims to achieve sustainable aquaculture through the power of technology and innovative solutions.

The exterior dimensions of the Umitron Cell, a smart feeding machine, are 1,080×840×1,110 millimeters, with a tank capacity of approximately 400 liters.

Global per capita consumption of seafood has roughly doubled over the past half-century, a pace that shows no signs of slowing today. Demand is driven by the increased intake of animal protein due to improved living standards, particularly in emerging countries, as well as the growing number of people choosing seafood over meat as part of global trends in health consciousness.

While the outlook for the aquaculture industry appears promising in light of this increasing worldwide demand for seafood, the industry also faces numerous challenges.

One issue is rising feed costs. Feed expenses account for 60 to 70% of production costs in aquaculture. The feed primarily consists of fish meal, which is made by drying and pulverizing sardines and other fish. However, sardines are used not only for aquaculture feed but also for human consumption, food additives, and livestock feed. This demand has made prices soar, imposing a significant burden on the industry.

Another issue is the labor burden. Daily feeding operations require workers to take boats to offshore fish pens and perform feeding chores multiple times from morning to evening. During bad weather, they must work for long hours in dangerous conditions.

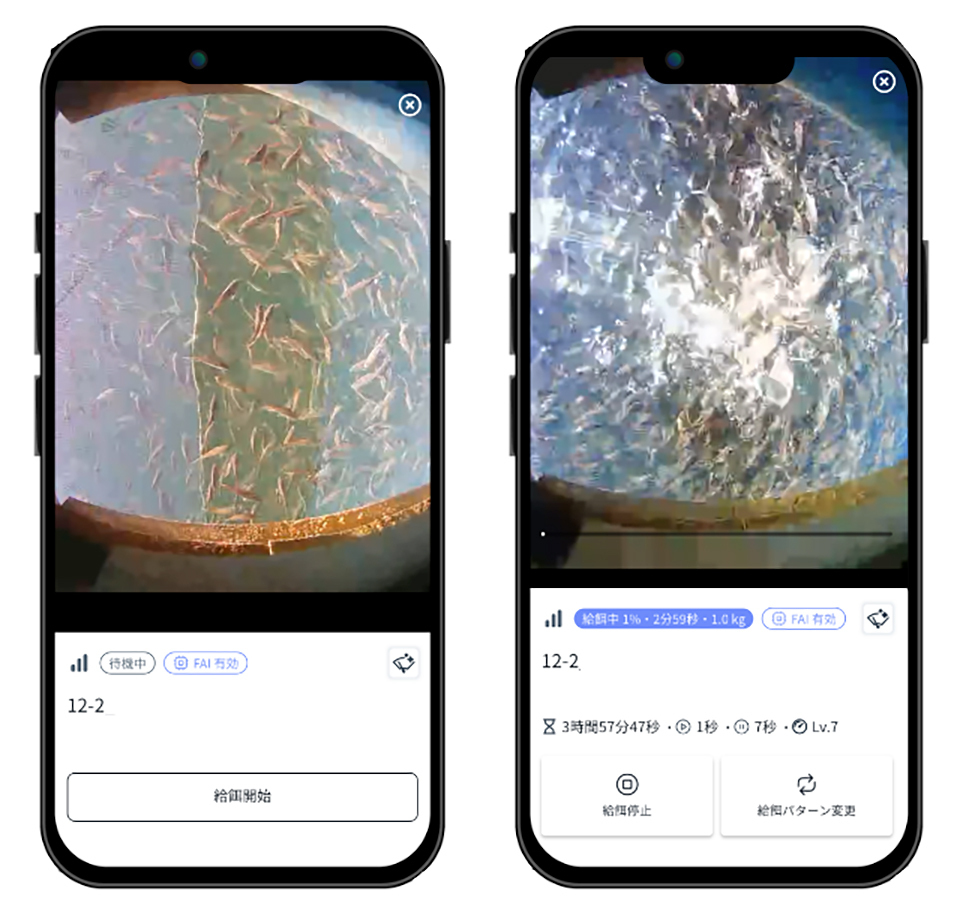

Red sea bream feeding time as viewed on the Umitron Cell mobile app screen.

The Umitron Cell, a smart feeding machine that utilizes AI technology, offers a solution to these challenges. A camera attached to the bottom of the unit captures real-time video of fish swimming in the pen. Workers can perform feeding operations remotely while watching the video on devices like smartphones. What’s revolutionary is that AI can assess the appetite of the fish and optimize the amount and speed of feed dispensing.

FUJIWARA Ken, co-founder and CEO of Umitron K.K., the company that developed the Umitron Cell, explains: “Fish vary the amount of feed they consume based on such factors as their physical condition and the water temperature. So we accumulate video data of fish eating feed and train AI to score the degree of fish appetite, allowing workers to optimize feeding operations.”

Until now, aquaculture sites relied on the experience and intuition of veteran fishers to determine the optimal amount of feed. The Umitron Cell has made this expertise visual and shareable.

The sharing of expertise as data has already brought numerous benefits. Previously, water quality deterioration from uneaten fish feed was a problem. Optimized feeding has reduced food waste and cut feed costs by 10 to 20%. Additionally, providing the right amount of feed at the right time has improved fish growth, making it possible to ship fish within a shorter time frame while maintaining the same fish size and quality at shipment time.

The ability to conduct feeding operations remotely also means that producers no longer need to travel frequently to the fish pens. This not only significantly reduces working time at sea, but also cuts fuel costs for boats traveling back and forth to the pens.

Fish raised using the Umitron Cell are labeled “Seafood Farmed S.M.A.R.T. UMITRON” and sold through supermarkets and restaurants nationwide as well as overseas.

“I wanted to feel that my research was directly helping people’s lives. So when I hear the happy voices of aquaculture operators saying things like ‘After introducing the Umitron Cell, I was able to attend my child’s sports day for the first time,’ I really feel a sense of purpose,” Fujiwara says.

Umitron aims to develop AI models optimized for the characteristics of different regions of use. “Water temperatures change every year, and environmental conditions differ from bay to bay even within the same region,” Fujiwara explains. “By collecting local data, we believe we can provide solutions optimized for each region.”

Fujiwara’s research achievements at JAXA also find use in the Umitron Pulse, a high-resolution marine data service for aquaculture that utilizes satellite remote sensing technology. This makes marine environmental data observed by satellites, such as water temperature, oxygen concentration, and ocean currents, available worldwide. Access to this data enables aquaculture operators to make more accurate and efficient decisions regarding feeding amounts and shipping schedules.

Currently, Umitron is expanding its services abroad to Europe and Southeast Asia to leverage the AI technology installed in the Umitron Cell. Fujiwara says he continues to aim toward the goal of achieving sustainable aquaculture by providing innovative solutions utilizing AI and satellite data. It’s a vision that offers a beacon of hope for the future of food production.

FUJIWARA Ken, co-founder and CEO of Umitron K.K. He says, “When people eat delicious fish, I want them to think about the sustainability of fisheries and aquaculture.”