The world produces 430 million tons of plastic every year. The current practice of making plastic from fossil resources and disposing of it in large quantities has become a major issue because it exacerbates global warming as well as marine pollution. However, a major Japanese chemical manufacturer has developed a technology that creates biodegradable plastic by feeding CO2 to bacteria. The company is now engaged in production demonstrations as a step toward mass production.

Kaneka Corporation’s Green Planet biodegradable polymer can be processed into products ranging from straws and shopping bags to tableware and food container packaging.

Plastic, a material indispensable to our daily lives, is mostly made from petroleum-derived substances. The energy used in the manufacture and incineration of plastics contributes significantly to global warming due to the emission of large amounts of carbon dioxide (CO2).

Moreover, improperly disposed plastics that flow into the ocean through rivers or sewage systems break down into microplastics—fine plastic fragments less than 5 millimeters in diameter. These accumulate in the bodies of marine organisms and eventually enter human bodies as well, raising concerns about their adverse effects on health.

Japanese chemical manufacturer Kaneka Corporation has developed a technology that can solve these problems. The technology uses bacteria that utilize CO2 as a carbon source to efficiently produce biodegradable plastic—that is, plastic that can be degraded by microorganisms. Fantastic as it may sound, this technology has the potential not only to help reduce CO2 but also to ensure that even if the plastic accidentally flows into the ocean, it will be biodegraded by microorganisms living there, eliminating concerns about marine pollution. In other words, it’s a technology that solves two critical problems at once.

The key to this breakthrough is hydrogen-oxidizing bacteria. Such bacteria have existed in natural environments like the soil and the sea since the origin of life on Earth.

Plants use solar energy to break down CO2 and convert it to organic compounds such as starch, which they use as an energy source for growth. Similarly, when hydrogen-oxidizing bacteria are provided with hydrogen, oxygen, and CO2, they can convert the CO2 into organic compounds using the energy generated when they oxidize the hydrogen. And just as humans store energy as fat, the bacteria accumulate these organic compounds within their bodies.

The organic compounds stored inside the bacteria are biodegradable polymers, macromolecules that serve as the raw material for biodegradable plastics. Using synthetic biological methods, Kaneka has succeeded in developing bacteria that generate high-strength yet biodegradable plastics suitable for processing into a variety of products.

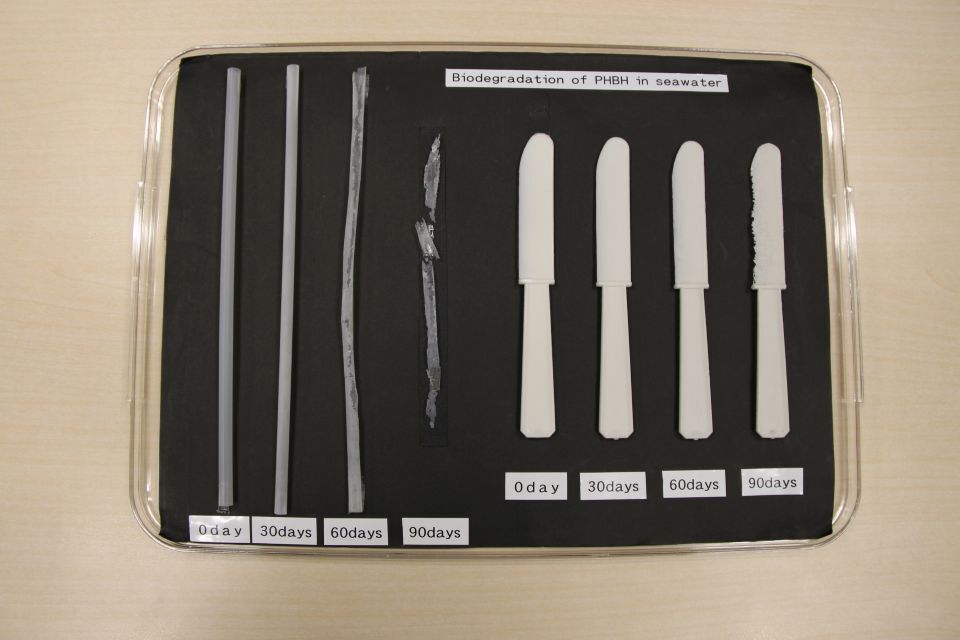

Biodegradable plastics are highly varied, with different raw materials and manufacturing methods. Plastics that completely biodegrade in natural environments are rare, such as those that only decompose in high-temperature compost environments. In seawater, which contains relatively few microorganisms, experiments show that degradation can take more than a year. Kaneka’s Green Planet biodegradable polymer, however, has been confirmed to degrade not only in soil but also in seawater environments, demonstrating that it can contribute to solving the marine plastic problem.

The company currently produces its biodegradable plastic from biomass, but development is advancing toward the mass production of CO2-based materials, with a target of commercial-scale demonstrations in fiscal 2030.

An exhibit showcasing Kaneka’s biodegradable plastic technology is on view at the Japan Pavilion of Expo 2025 Osaka, Kansai, Japan, which takes place from April to October 2025. The display illustrates how biodegradable plastic bowls can be created from CO2 stored in cylinders, allowing visitors to see firsthand a futuristic vision of “circular manufacturing.” The exhibit also demonstrates how these plastic bowls are degraded by microorganisms in water tanks, converting them into CO2 and water. Viewers will come away with a better understanding of potential solutions to the microplastics crisis.

An exhibit at the Japan Pavilion of Expo 2025 Osaka, Kansai, Japan shows how CO2 stored in gas cylinders (at left) are absorbed by hydrogen-oxidizing bacteria to create biodegradable plastic bowls (at right). Photo courtesy of the Ministry of Economy, Trade and Industry

Kaneka’s Green Planet biodegradable polymer at different stages of decomposition by microorganisms in seawater. Rather than simply breaking apart through hydrolysis, the plastic is broken down by the microorganisms to the molecular level, ultimately returning it to the natural environment as CO2 and water.

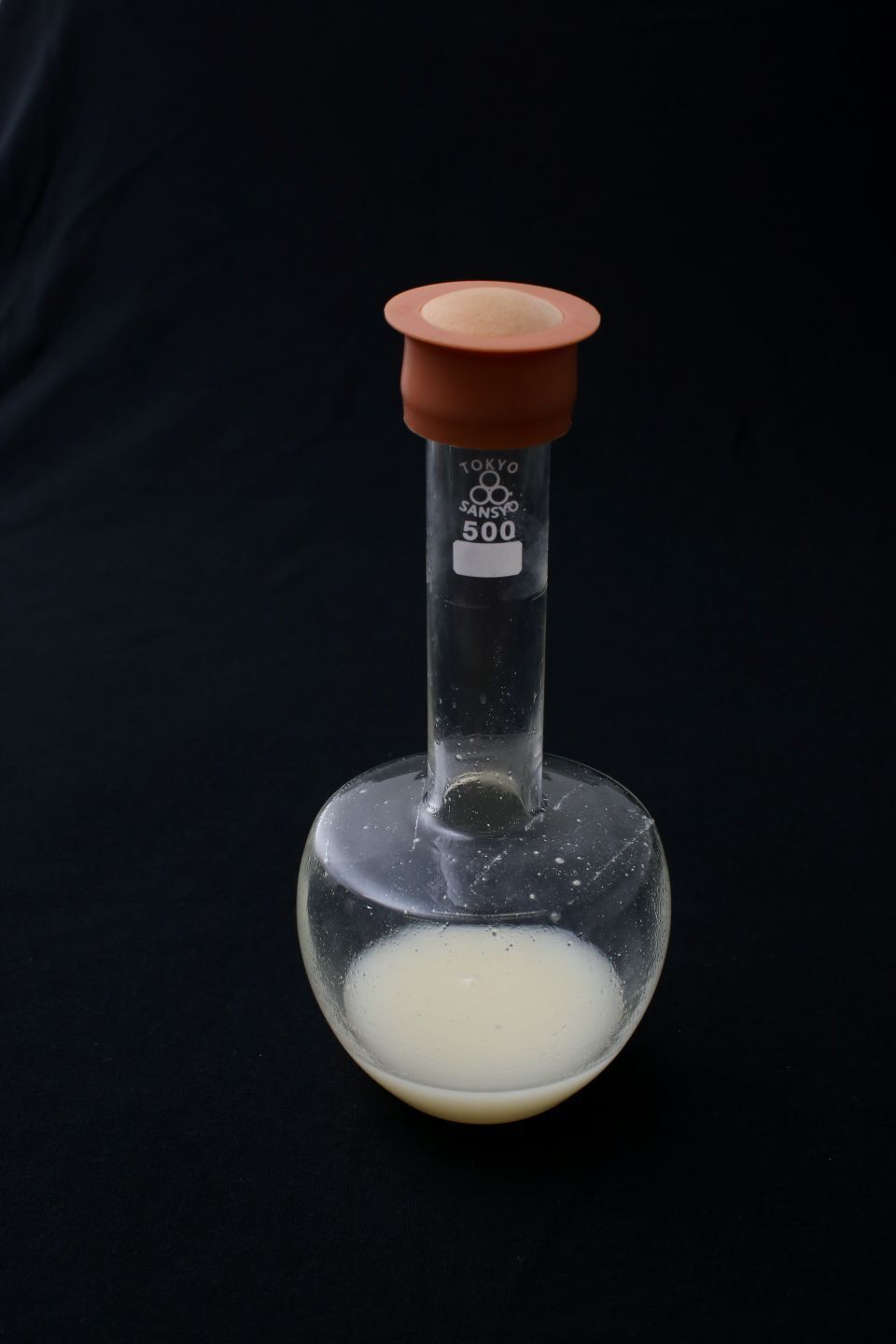

Kaneka has set up a 200-liter bacteria cultivation tank at a manufacturing site in Hyogo Prefecture, where it currently conducts scale-up experiments aiming toward practical application. The company plans to scale operations up to a capacity of 100,000 liters by fiscal 2030.

SATO Shunsuke, head of Kaneka’s CO2 Innovation Laboratory, leads the research. Speaking of the challenges involved, he says, “The biggest issue is ensuring safety. We supply CO2, hydrogen, and oxygen to make the bacteria produce polymers, but there’s a risk of explosion when hydrogen and oxygen mix. Therefore, we’re collaborating with a leading domestic engineering company to design and develop a safe plant.”

Left: A hydrogen-oxidizing bacteria cultivation plant installed at a factory in Hyogo Prefecture.

Right: Hydrogen-oxidizing bacteria being cultured in a flask.

A hydrogen-oxidizing bacteria cultivation plant installed at a factory in Hyogo Prefecture.

Hydrogen-oxidizing bacteria being cultured in a flask.

Another challenge is how to procure large amounts of hydrogen and CO2. “For hydrogen, we envision using renewable energy to produce it through the electrolysis of water. Ideally, we would like to capture CO2 from the atmosphere, but the concentration would be too low. We’re watching the latest global technology developments to find the optimal method,” says Sato.

Recent years have seen attention focused on carbon recycling initiatives, where CO2 is treated as a resource and reused as material or fuel to reduce atmospheric emissions. If the new technology developed by Kaneka is implemented on a wide scale, it could not only solve both the problems of global warming and plastic waste, but also provide an important step toward achieving a carbon recycling society.

SATO Shunsuke, head of Kaneka’s CO2 Innovation Laboratory. “Our biodegradable plastic should be able to replace any and all existing plastic products. We’ll start by applying it to short-lifespan products like disposable bags and tableware, and eventually, we hope, expand into textiles as well,” he says.