Reports indicate that over 8 million tons of plastic waste are released into the world’s oceans every year. Among these, microplastics (MPs)—plastic debris broken down into tiny particles by ultraviolet light and wave action—are extremely difficult to collect and have become a significant factor in severe marine pollution. Two Japanese companies have teamed up to develop a device that holds promise for solving this problem by collecting MPs during sea voyages.

Microplastics take anywhere from decades to centuries to decompose in natural environments. Once they enter the ocean, they remain for extended periods, adversely affecting water quality and marine life. Alistair Berg / DigitalVision via Getty Images

The problem of marine plastic waste has become increasingly urgent on a global scale in recent years. Microplastics (MPs) less than 5 mm in diameter are particularly concerning as they spread via currents throughout the world’s oceans, potentially harming not only marine but also human life. MPs that have entered the ocean are difficult to collect using conventional filters or nets. Also, localized collection efforts have limited effectiveness because MPs are widely dispersed and there is currently no established technology for their recovery.

To address this global challenge, Japanese shipping company Mitsui O.S.K. Lines, Ltd. and industrial equipment manufacturer Miura Co., Ltd. have jointly developed a groundbreaking device capable of collecting MPs while ships are at sea. Since June 2022, this device has been installed on the car carrier Emerald Ace operated by Mitsui O.S.K. Lines.

The two companies launched their joint project in 2020. The MP collection device currently installed on the Emerald Ace represents the second generation of the technology they developed together.

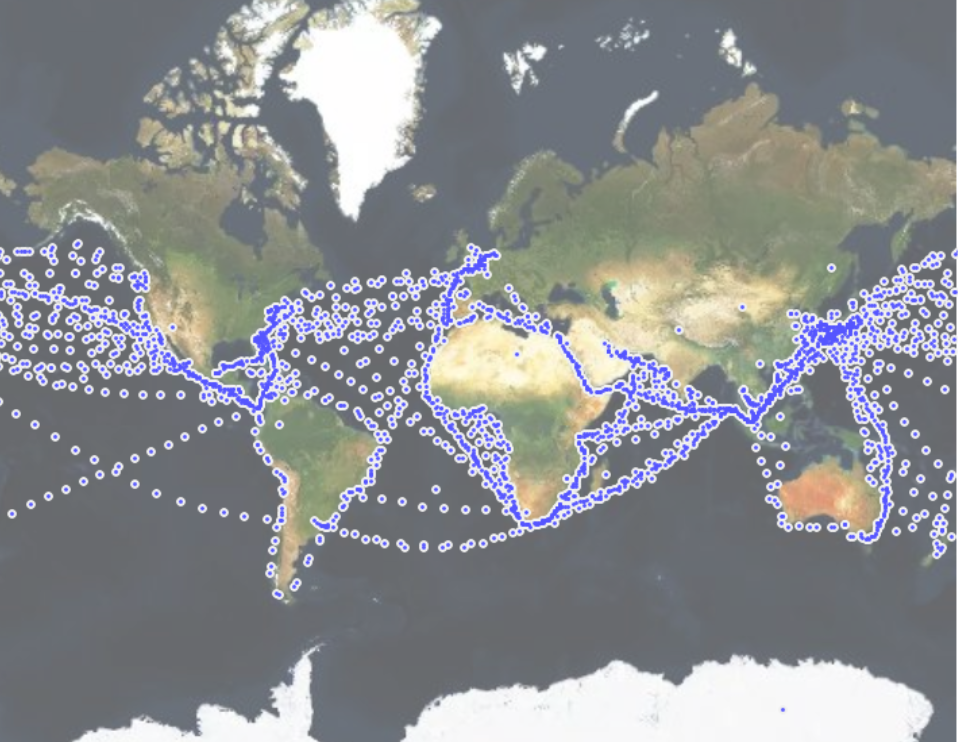

Exterior view and operational map of the car carrier Emerald Ace equipped with the new microplastic collection device. The record of the ship’s route shows that it has been collecting MPs across oceans worldwide.

When ships unload cargo, they pump in seawater from the harbor and store it on board as ballast water to maintain balance. However, when a ship loads new cargo at its next port of call, the discharge of this ballast water risks transferring aquatic organisms to a different marine habitat, potentially damaging the ecosystem where it is discharged. To prevent this, ships are required to install ballast water treatment systems. The first-generation MP collection device placed a special strainer on the discharge line for this treated ballast water to capture the MPs in the water.

However, the first-generation device had two shortcomings. First, seawater intake was limited to the cargo unloading process, restricting possible locations for MP collection. Second, when the MP collection strainer became clogged with MPs and other materials, the discharge line flow had to be halted for cleaning, increasing the workload for the crew.

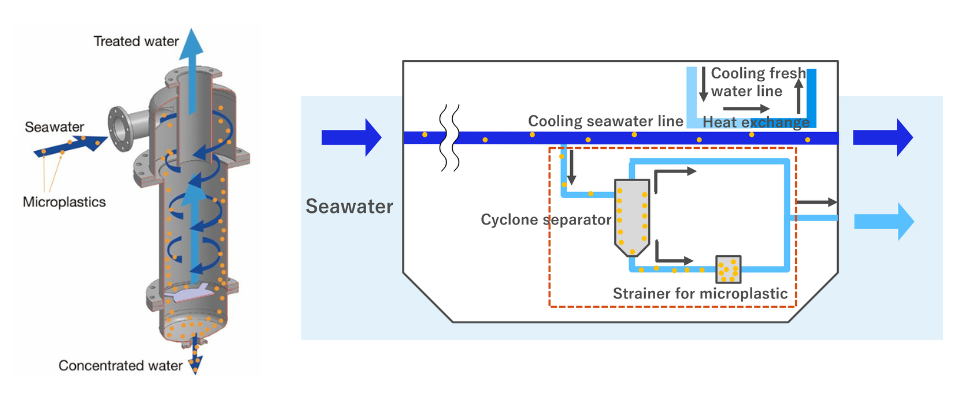

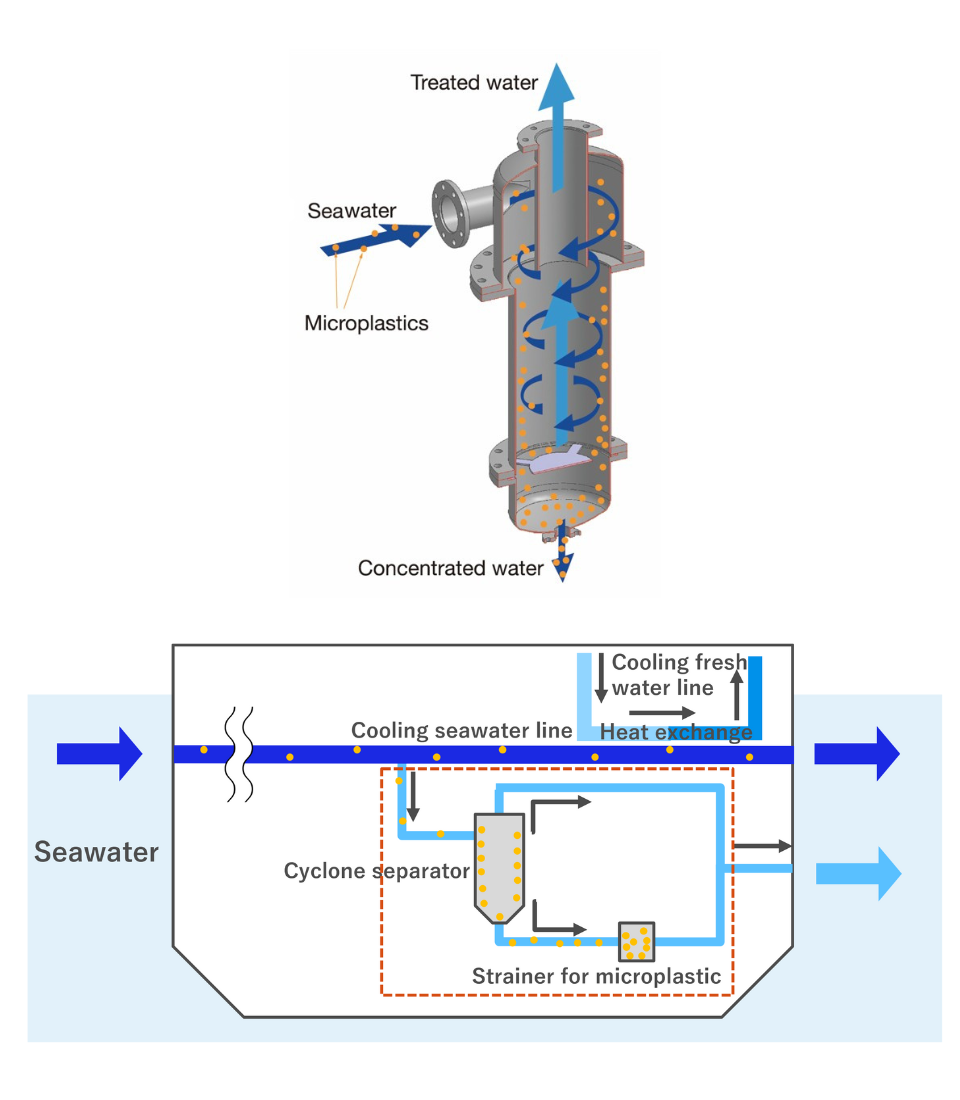

For the second generation, instead of using the ballast water intake line, the developers diverted the seawater intake line used for cooling engines and other equipment, and installed a cyclone separator, a device that centrifugally separates MPs from seawater.

This device works by separating out water containing high concentrations of floating materials like MPs, efficiently capturing these materials and allowing their recovery with a strainer. Moreover, since the cooling line constantly draws in water while the ship is underway, MPs can be continuously collected. As a result, this second-generation device can process approximately 70 times more seawater in a year than the first generation did. Moreover, diverting only part of the cooling line to this device allows cleaning of the MP collection strainer without stopping the cooling line flow, reducing the crew’s workload.

Structural and conceptual diagram of the new microplastic collection device.

Structural and conceptual diagram of the new microplastic collection device.

Mitsui O.S.K. Lines provides data on the composition, quantity, location, and timing of recovered MPs to the Ministry of the Environment’s “Atlas of Ocean Microplastic” (AOMI) database. Since AOMI gathers floating MP monitoring data from researchers, institutions, and governments worldwide, global MP researchers can access and utilize this data.

In another application still in the research stage, the developers have successfully created raw materials for solid fuel by combining recovered MPs with microalgae. This technology holds promise not only for marine environmental conservation but also for realizing a circular society through waste recycling.

NISHI Shuichi, General Manager of the Technology Research Center, Ship Technical Unit of Mitsui O.S.K. Lines, says: “Currently, we have installed the system on a car carrier that navigates wide areas, but in the future, if necessary, we can install it on vessels operating on regular routes to conduct fixed-point monitoring as well. Through these initiatives, we hope to contribute to the conservation of the global marine environment.”

Project leader NISHI Shuichi, General Manager of the Technology Research Center, Ship Technical Unit, Mitsui O.S.K. Lines, Ltd.