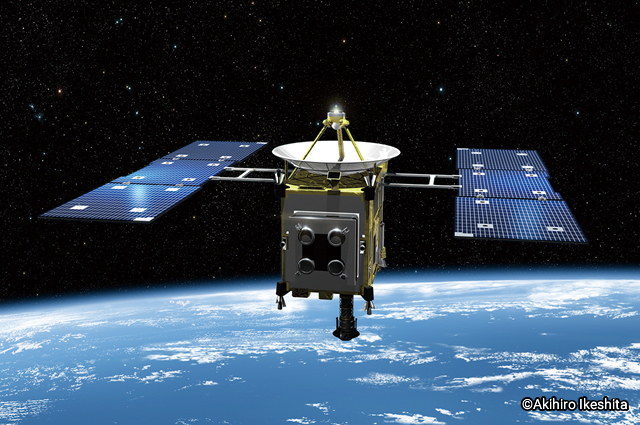

A material with truly outstanding properties, carbon fiber is only 1/4 the weight of iron while being 10 times stronger. Carbon fiber’s applications include sports equipment such as golf clubs and tennis rackets, and parts for automobiles. It also maintains stable performance under severe conditions such as extreme heat and cold. Because of these properties, it began to be used as a structural material for the vertical tails of aircraft and their outer body plating, and today it’s even being used on containers for the solid boosters of rockets and the hull frames of satellites.

As the world’s largest manufacturer of carbon fiber, Toray Industries, Inc. is actively expanding its global production systems, and currently conducts its business through an international network with a fournode system of production bases in North America, Europe, Asia and Japan.

Toray’s Corporate Communications Department Manager, Toshiki Matsumura, explains, “Our company’s basic principle is to take root in the regions where we conduct our business, contributing to employment and industrial development as we grow. In addition, by establishing business bases in the vicinity of our customers, we closely work together and endeavor to promptly respond to their needs. This, in fact, leads us to technological innovation.” A good example of this is the application of structural materials to airplanes. In the field of airplanes, starting in the 70s, carbon fiber was used as interior material for parts such as door components. But to replace the aluminum alloy that was the most commonly used structural material at the time for the fuselage and other critical components, absolute reliability was a must, and certain issues had to be overcome. The structural material was produced by overlaying sheets of carbon fiber, but when a certain area of the material peeled off when suffering a strong impact such as being struck by a bird during flight, it was discovered that there was a possibility that the strength of that area would decline. This was pointed out to Toray’s engineering staff by U.S. aircraft manufacturer The Boeing Company. Through research and development, the staff came up with the solution of sticking the sheets together by impregnating them with an adhesive resin, successfully developing a material whose strength would not be downgraded even when a section of the material is stripped.

Toshiki Matsumura serves as Manager of the Corporate Communications Department of Toray Industries, Inc. Toray currently conductsits business in 26 countries and regions.

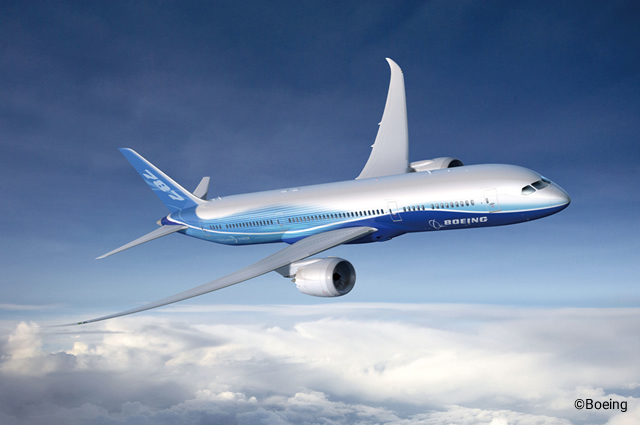

Impressed by Toray’s innovative solution, Boeing adopted Toray’s carbon fiber as the material for its Boeing 777 tail assembly in 1989. In the years that followed, the use of carbon fiber expanded with each newly developed aircraft, and in 2009, the Boeing 787 took its maiden flight as an innovative model featuring carbon fiber in the fuselage, main wing, central wing and tail assembly. Today, this Boeing 787 is owned and/or operated by 69 airlines and leasing companies in 49 countries around the world.

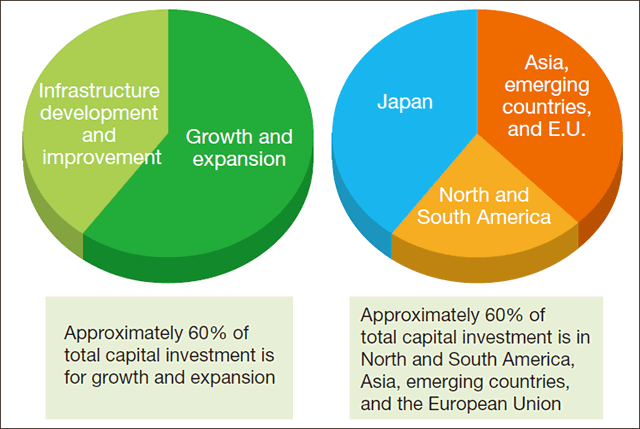

Backed by such successes, Toray conducted a worldwide capital investment of USD 3.6 billion (JPY 400 billion) in the three-year period spanning fiscal years 2014 to 2016. Approximately 60% of this investment was in North and South America, Asia, emerging countries, and the European Union. As a result, the company has a total of 28,371 employees overseas as of March 2017. In addition, Toray concluded a comprehensive, long-term supply contract with Boeing in 2015 to provide carbon fiber for the new 777X aircraft, and invested USD 446 million (JPY 50 billion) for a U.S. production facility in Spartanburg County, South Carolina that is now under construction. This investment is the first step of a USD 893 million (JPY 100 billion) outlay in the U.S. market which Toray intends to complete by 2020.

Matsumura explains, “The scale of the U.S. market is huge. It’s also attractive in that you can conduct your business with peace of mind in an environment where your rights are protected by laws and regulations. For the future, we hope to continue finding success with exciting new projects together with the people of our business bases in the United States and around the world.”