After suffering severe damage during the Great East Japan Earthquake of March 2011, Fukushima is building new industrial infrastructure toward its reconstruction. The robotics and drone industries are one part of that effort. With an exceptional test field covering land, sea, and air, Fukushima is striving for sustainable development through regional collaborations.

The Fukushima Robot Test Field was built in Minamisoma City, Fukushima Prefecture. To develop the existing technology, researchers conduct demonstration tests and flight drills to inspect infrastructure and respond to disasters in hypothetical real-world environments. One goal of the test field is to build up a local robotics industry. Shown right is a scene from an experiment at the test field.

“We’re motivated by the idea of spreading Japan’s aviation industry from Fukushima Prefecture,” says SOTANI Hideji, president of Eams Robotics Co., Ltd., an industrial drone manufacturer based in Minamisoma City, Fukushima Prefecture.

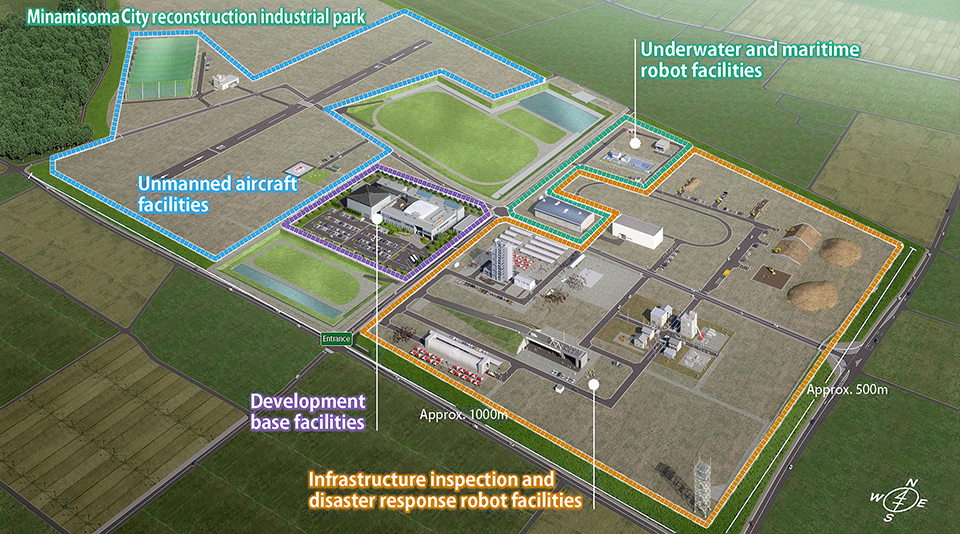

Overview of the Fukushima Robot Test Field

Initiatives to build up various industries are proceeding under the Fukushima Innovation Coast Framework, a national project that seeks to build industrial infrastructure in the prefecture for its reconstruction after the 2011 earthquake. The robotics and drone industries are a critical area under the framework. The Fukushima Robot Test Field was established as a research base that can—exceptionally, by world standards—reproduce the actual operating conditions of ground, maritime, underwater and aerial robots, including infrastructure and disaster zones. The field is now the site of ongoing innovative research and development.

The main body and the unit can be separated, allowing the drone to be used for multiple purposes. In the event of a disaster, it can be equipped with a camera that can transmit images of the damage (left) and a speaker for guiding evacuation (right).

Drones are expected to play an active part in inspecting and surveying bridges, dams, wind power plants, and other sites that are hard to access by humans, as well as in assessing the situation at the time of a disaster. The picture depicts a bridge-survey experiment.

Eams Robotics is developing state-of-the-art technology, including drones equipped with AI to keep them aloft. The company is mainly focused on using such drones for inspections and surveys in high or dangerous places not easily accessible by humans, including bridges, dams, and wind farms, as well as for the transportation of supplies to hard-to-reach locations such as mountainous areas and remote islands, and for the gathering of information during disasters. Using drones that can transmit live footage of major disasters could allow for quick situational assessment and a more targeted initial response. “We’re developing a design that allows a solo operator to control multiple drones. Last November, we conducted a field test in which one person simultaneously flew three drones in a search operation at a fire site. To utilize drones as social infrastructure, costs need to be reduced by controlling several of the machines simultaneously,” President Sotani said.

To develop the drone market with an “all-Fukushima” approach, Eams Robotics has also implemented horizontal cooperation with other local companies based in the Hamadori area, which includes Minamisoma City. “We are starting to build a sales network and initiating collaboration on technical matters as well. We want to foster the drone industry by capitalizing on each company’s strengths,” Sotani said enthusiastically, adding that he also hopes to energize Fukushima’s industry as a whole.

SOTANI Hideji, president of Eams Robotics. The company co-established Fukushima Next Generation Aviation Strategy Promotion Council (FAS), which is working on training professionals and collaborating with other local companies so that Fukushima can build a world-leading industry.

Cultivating the next generation of talent will be essential to growing a drone industry with strong local roots. Sotani gives talks about drones at local junior high schools, and the company has started using the visits as opportunities to take in local students as interns. “We aim to be a company at which the children of Fukushima will choose to work.”

Eams Robotics is also eying markets beyond Japan’s shores. Although foreign companies account for a large share of the global drone market, Sotani sees additional opportunities for Japanese companies to make inroads there. “I believe that Japanese firms excel in promptly troubleshooting problems and offering flexible customization according to customer needs. We can be effective in actively developing new applications for drones, as well as in the field of information security,” he said.

The “Aerial Industrial Revolution” that Fukushima’s advancements in drones will help make a reality is going to take off in a grand fashion in tandem with the prefecture’s reconstruction.