Injection-molded plant-based biodegradable plastic, which can be mass-produced with advanced technology, is the latest ray of hope from Japan to combat plastic marine litter

Marine plastic litter doesn't only detract from beautiful nature. Microscopic plastic has a serious effect on both marine life and humanity as well.

Biodegradable baby tableware expertly designed to be completely curved. Inquiries are coming in from around the world due to the trust-inspiring “safe for babies and earth-friendly” message.

http://iiwan.jp/?mode=f82

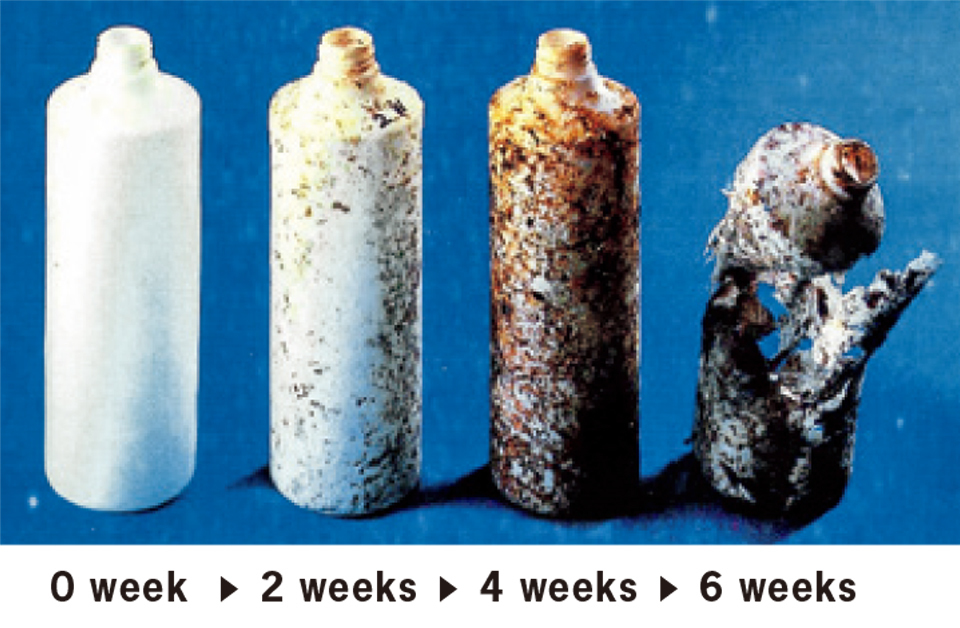

State of biodegradation under composting conditions for two, four and six weeks. Photo courtesy of Japan BioPlastics Association.

Petroleum-based plastic has now been part of human daily life for more than 70 years.

Plastic has brought convenience, but now is inflicting serious damage to the Earth. The amount of plastic waste drifting throughout our oceans has been estimated to be currently about 150 million tons, a figure rising by about eight million tons each year. [1]

Showing promise as a fundamental solution to this grave problem, a revolutionary group of technologies is attracting attention. Developed by Michio Komatsu, a Japanese mold technology expert, they comprise numerous processes for manufacturing biodegradable plastic products by injection molding.

Komatsu, president of a professional engineer’s consulting firm in Iwaki City, Fukushima Prefecture, is focusing on the injection molding of a certain plant-based biodegradable plastic called polylactic acid, which is raising interest worldwide. Aiming to use it to replace conventional petroleum-based plastics, Komatsu has been developing practical applications for it since 2005. Polylactic acid is decomposed by microorganisms in the soil or seawater, and if disposed in compost, it will return completely to nature as water and carbon dioxide in the space of only several months.

However, its development has not been easy so far. For example, the raw material cost of polylactic acid is expensive, it has low heat resistance, and forming it by injection molding is hard due to its poor fluidity. All that has made it difficult to commercialize.

“Always short of funding, I managed to continue my research and development by applying for competitions. I kept persevering by holding on to the simple belief that we had to start using polylactic acid to begin combating pollution of the ocean,” explains Komatsu.

Most people who hear the term “bioplastic” instantly assume that it refers to environmentally friendly plastic created from a biological resource. However, there are many types of plastic. Polylactic acid is made from plant-based materials and naturally decomposes, but other bioplastics aren’t biodegradable, while some petroleum-based plastics are.

Among the various candidates, the entirely plant-based and biodegradable polylactic acid is most ideal for future use as an eco-friendly plastic that fulfills the criteria necessary to be considered harmless and non-toxic. Its raw ingredients are starch and lactic acid bacteria extracted from plants such as corn.

There is no one in the world currently that can surpass Komatsu, who has mastered various kinds of injection molding technologies for polylactic acid.

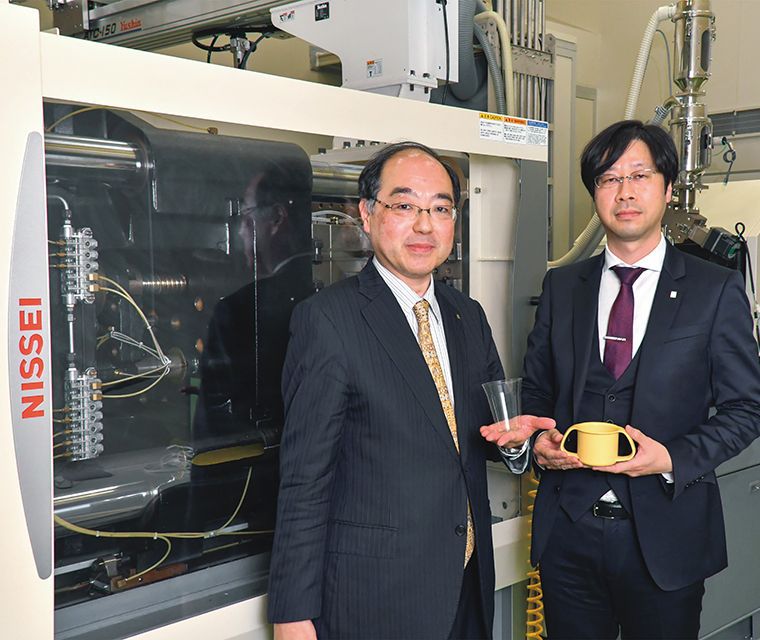

“As momentum picks up for taking global action to prevent pollution of the ocean, I am confident that our Japanese-originated technology will be increasingly needed in the world,” says Komatsu. Commercialization has already begun. The baby tableware series iiwan is a polylactic acid product that Komatsu jointly developed with Hoei Industry Co., Ltd. of Shinshiro City, Aichi Prefecture.

These products are gaining popularity through word of mouth as “eco-friendly and safe for babies,” and are now being exported to the world. Inquiries from potential buyers are rapidly pouring in from countries in Europe and Asia. Takahiro Miwa of Hoei Industry is enthusiastic about this. “Going forward, we aim to offer both Japan and the world safe and environmentally friendly plastic products for not only children but people of all generations,” he says.

As product development advances, the possibilities for this new plastic are rapidly expanding. In fact, it may not be long before polylactic acid plastic from Japan revolutionizes the very concept of plastic.

In front of the injection molding machine.

Michio Komatsu (Left): President of Komatsu & Associates, he is Director of Japan Society of Plastics Technology. In 2018, he received the Prime Minister’s Award, The Monodzukuri Nippon (Japan’s manufacturing) Grand Award (honored with the title of Master of Monodzukuri) for injection mold technology of polylactic acid.

Takahiro Miwa (Right): Executive Managing Director of Hoei Industry Co., Ltd., he joined Hoei Industry in 2002 and devotes much energy to the bioplastics products

business. The product iiwan received the Good Design Award in 2011.

[1] Data from the Ministry of the Environment’s “Study of Domains Targeted by the Ministry of Environment” dated March 15, 2017.