Regenerative medicine uses cells and other materials to restore the function of internal organs and to repair tissue that has been damaged or has ceased working properly. All over the world various research is rapidly moving towards real-world applications, and breakthroughs for further progress are on the horizon. Given these circumstances, the “three-dimensional tissue fabrication technology” developed by Cyfuse Biomedical K.K., a Japanese startup founded in 2010, is garnering much attention.

Until now, the creation of tissue or organs for regenerative medicine has primarily used artificial scaffold materials like gel and collagen, but Cyfuse’s technology makes it possible to generate three-dimensional tissue and organs using cells exclusively, without any scaffolds. For example, bones can be created based on cells extracted from a patient’s buttocks. Masahiro Sanjo, Cyfuse Board of Directors member and CFO, explains, “Tissue produced using only cells is also more compatible with the body and has a lower risk of infection. Once regenerative medicine using cellular bone, cartilage, blood vessels, and nerves becomes available, it can be an option that may reduce the stress for patients resulting from the removal or exchanging of artificial components that comes with conventional materials, and therefore greatly increase their quality of life.”

Cellular 3D Printer Brings New Hope

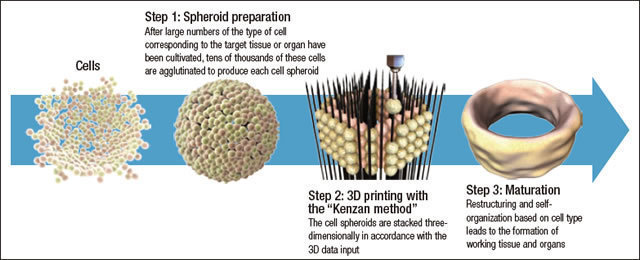

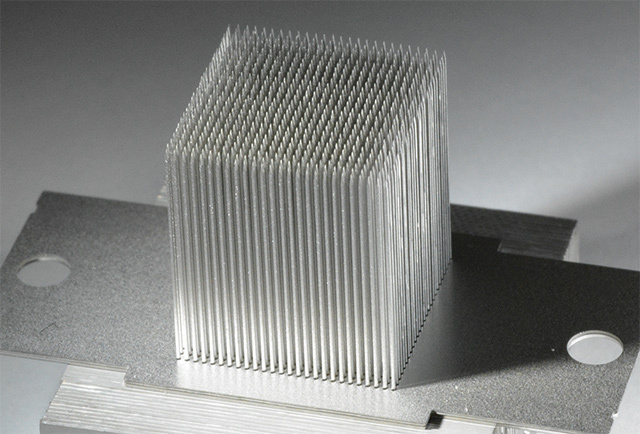

The “Kenzan method,” a platform technology for the three-dimensional stacking of cells

Tens of thousands of cells cultivated from a small sample extracted from the patient are agglutinated, producing cell-based structures 0.5 mm (0.02 in.) in diameter called “spheroids,” which are stacked on a jig containing a needle array (called a kenzan). Next, the spheroids of cells are made to fuse with each other utilizing the cells’ natural abilities inside a culture solution. Once they have matured, they are removed from the needle array.

Cyfuse Board of Directors member and CFO Masahiro Sanjo says, “It will take some time for such advanced regenerative medicine and the cell-based products developed with Japanese technology to become a new global standard, but I would like to work step by step towards accomplishing Cyfuse’s dream to ‘Create New Hope from Cells.’”

Cyfuse is unique in that it developed its Regenova device, which handles the task of automatically stacking the cells, in collaboration with Shibuya Corporation, a company most renowned for its production of bottling systems. Regenova, also referred to as a “Bio 3D printer,” uses a robot arm to stack the cells, which have been aggregated in small groups called “spheroids,” according to three-dimensional arrangement parameters that have been set using 3D design software. This cuts production time, which would amount to several dozen hours if researchers constructed the tissue manually, and improves consistency in the quality of structures produced. “Connecting high-level biotech research and engineering and then commercializing this connection is a generally difficult task because of the extent of mutual understanding required. However, many different individuals share Cyfuse’s ideal of ‘contributing to the rapid progress of medicine through the implementation of innovative technology’ and have helped bring about innovations through the fusion of biology and engineering. Since the Regenova system’s launch in 2012, it has spread both domestically and internationally, and research and development regarding its commercialization is accelerating at each of the institutions that have adopted it,” recounts Sanjo.

With Regenova, a variety of cell-based structures can be produced. Cyfuse is currently focusing its research and development on the generation of bones, cartilage, blood vessels, and peripheral nerves, for which there are the most significant unmet needs in medical settings. All of such research is carried out in conjunction with universities, research institutes, and private companies, and Cyfuse also receives support from governmental sources including national research and development agencies. The production of bones and cartilage has moved to the clinical trial stage, while that of blood vessels and peripheral nerves is still in pre-clinical development. Cyfuse is also involved in the development of liver structures to use as samples in the evaluation of newly developed medication and in the exploration of mechanisms that lead to disease. Expectations for such research in the field of drug discovery support are rising, since the risk of clinical trials involving human subjects will decrease once it becomes possible to conduct trials using liver structures produced only from human cells.

In the future, Cyfuse will continue its efforts to bring current research to market, spread advanced technology, initiate new technology development, and strive to expand its market share through technological innovation and lowering costs. “It is our hope to be able to provide patients with new options that will allow recovery from diseases and injuries that used to be considered impossible,” says Sanjo. “In order for that to happen, we mustn’t withhold our technology, but share it widely with the industry. We will keep working with as many universities, research organizations, and companies as possible to bring patients hope.”