Limex is a new material made from limestone that can be used in substitutes for paper and plastic products. It takes its name from “limestone” and “x,” a variable with no limit.

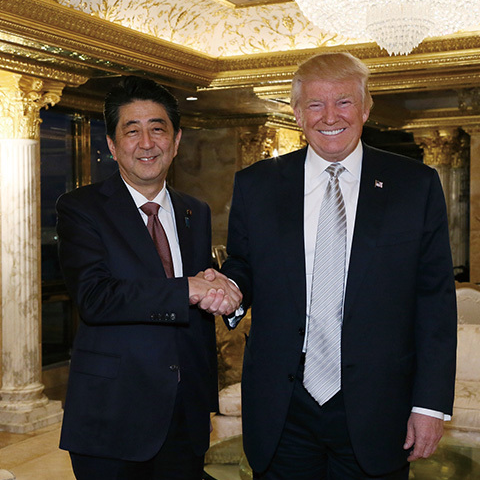

Nobuyoshi Yamasaki, an entrepreneur who had already established several businesses in his twenties, learned of the existence of the technology for producing paper out of stone in 2008. At the time it was not widely used, due to the weight and uneven quality of the paper. Yamasaki was drawn by the potential of this material, made with limestone, a globally abundant resource. He soon became involved in developing an improved version of the technology in hopes of contributing to the world. He found a partner, Yuichiro Sumi, a renowned authority in the paper industry, and together they came up with a new production method. In just nine months they succeeded in turning out a product that was light and stable in quality. In 2011 Yamasaki established TBM to develop, manufacture, and sell Limex.

Limex paper outperforms regular paper in its water-repellent quality and resistance to age deterioration. Businesses and government organs assessed it very favorably. Yamasaki recalls, “We received many positive responses based on the perspective of environmental impact, and this reaffirmed my belief in the material’s potential.”

Preserving forests and water

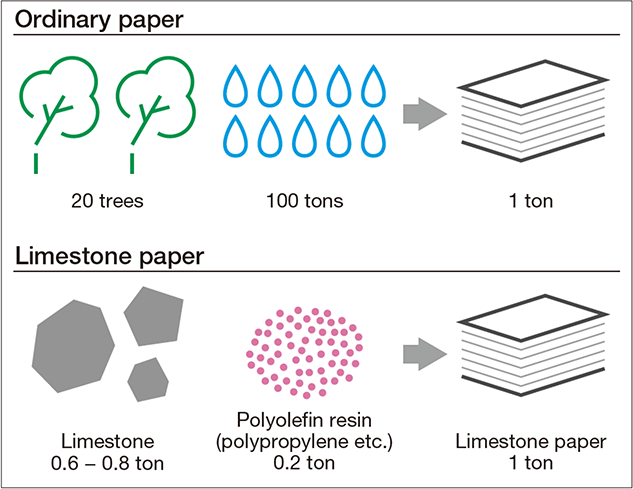

Global consumption of paper is expected to double from the present level by 2030. While 1 ton of regular paper requires 100 tons of water to produce, Limex paper can be made with virtually no water. If 5% of the world’s paper can be replaced by Limex, in 2030, it will save a year’s worth of water for 220 million people.

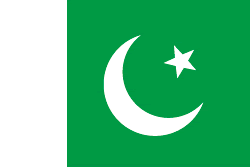

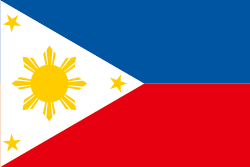

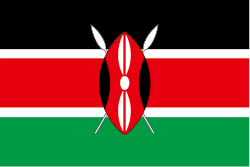

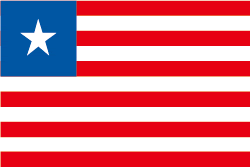

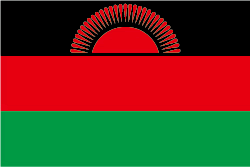

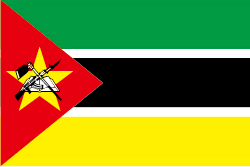

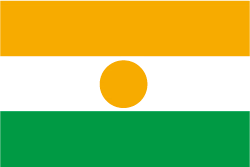

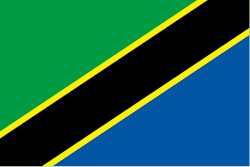

Since Limex paper does not use wood as a raw material, it can contribute to the preservation of forests. Another advantage is that it requires almost no water to produce. Limestone is readily available in places across the globe, and Limex can easily be made even in arid countries and regions. In addition, Limex paper manufacturing plants can be much smaller in scale than regular paper plants.

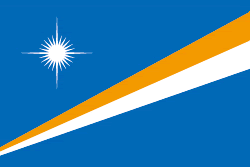

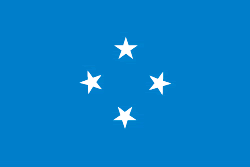

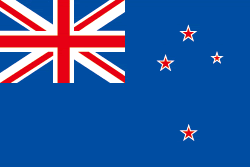

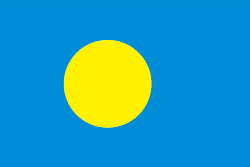

Yamasaki envisages future exports of Limex plants as model facilities to carry out local production for local consumption, combined with recycling. Touring the globe to find business partners, he has found great interest, with special enthusiasm from regions where water is scarce, such as the Middle East and Singapore.

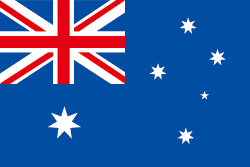

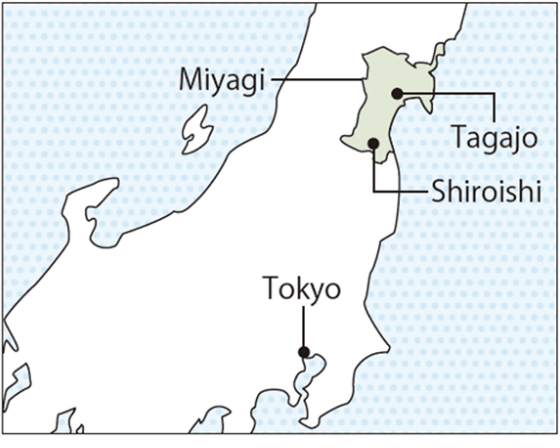

Yamasaki has also won recognition for his contribution to the reconstruction effort in the area struck by the March 2011 Great East Japan Earthquake. In February 2015, TBM completed a pilot plant in Shiroishi, Miyagi Prefecture, with an annual production capacity of 6,000 tons; it also serves as a research and development facility. And a second plant is being built in Tagajo, also in Miyagi, scheduled for completion in December 2017, with a production capacity on the order of 30,000 tons.

“I was sure that this business would serve the people of the world, and so I enthusiastically tackled the technological and financial challenges,” says Yamasaki. His dream is “to build plants in countries lacking water resources and to make Limex notebooks and textbooks for their children.”

Lightweight and waterproof

Limex paper is waterproof; it can be used outdoors and can be written on under water. And it is lighter in weight than existing types of stone paper. The bottom photo shows a disaster information card making use of these advantages.

A simple manufacturing process

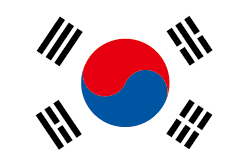

Limex is made by mixing finely powdered limestone and polyolefin resin while adding heat. The company received a Japanese patent for its production method in January 2014, and its international patent applications have been approved or await approval in 43 countries.