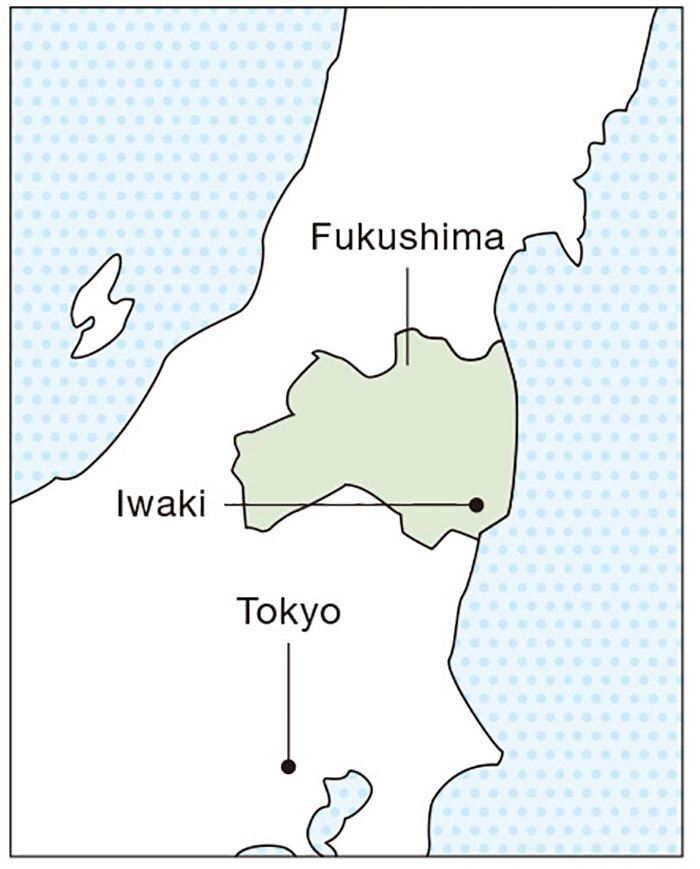

Iwaki, Fukushima Prefecture, located 200 kilometers (125 miles) north of Tokyo, is home to Merck’s Onahama Site, one of several Japanese production facilities of the German-based worldwide leader in the pharmaceutical, chemical, and life science industries. The factory is a pivotal production and R&D base for effect pigments and functional materials, serving as a pillar of the company’s global business. The key products developed at the Onahama facility supply markets all around the world, including North America and Europe, and the site is becoming increasingly important for the company.

Ralf Annasentz, president of Merck’s Japanese arm, explains that the company initially established its Japanese operation in 1968 to tap into Japan’s market, which was rapidly expanding at the time. But later Merck decided to expand this operation, turning it into the company’s Asian base. As part of this move, Merck established the Onahama Site in Iwaki in 1984 as a production center for pigments.

Merck’s choice of Iwaki for its production facility was informed by a number of considerations: The location offered access to high-skilled labor, abundant water necessary for production of pigments, and easy access to Tokyo. Not only that, but the local community provided strong and enthusiastic support, which was a key factor.

And the prefectural and municipal governments helped procure suitable land and access to water resources. Innovation has been a mainstay of Merck’s business, with the R&D facility at the Onahama Site actively involved with different partners, including universities and industry-leading companies. As Annasentz explains: “Japan is rich in different players that can help bring innovation to the marketplace.” Tsuguto Takeuchi, Onahama Site director for performance materials, points to a Japanese focus on communicating closely with customers. This was key in two of the company’s most representative products exclusively developed at the Onahama Site, the color effect pigments Xirallic® and Meoxal®. Both are staples in the auto industry and other sectors for their unrivaled quality, and they are the result of close communication with customers during the R&D phase of production.

Annasentz has high praise for employees at the Onahama Site, who largely hail from the local community. “They have a high level of personal engagement and the mentality to always deliver to the best of their ability,” declares Annasentz. “Everyone tries to be part of the solution to problems.” He notes that such traits are indispensable to a company operating in a highly competitive and rapidly changing industry. Merck has benefited from local industrial high schools, which have continued to be a source of skilled graduates ready to step into jobs at the site’s production operations.

When the Great East Japan Earthquake struck on March 11, 2011, damage to equipment at the Onahama Site and water stoppage brought the plant’s pigment production line to a halt, causing a global stir as manufacturers were temporarily deprived of a necessary resource. However, the combined efforts of the Iwaki community helped keep the impact to production to a minimum. The experience helped strengthen Merck’s ties with the community, which joined the company in celebrating the thirtieth anniversary of the Onahama Site in 2014.

Local communities in Japan’s nonmetropolitan regions are proud to host global firms, and they extend such firms their all-out support. In return they benefit from these companies’ activities, particularly through the jobs that they create for local workers. Japan’s regions are full of places like Iwaki, cities that are ready and able to build vibrant win-win relationships with companies that establish production or R&D bases. These regional cities are fully equipped to take in global firms, and they are actively seeking such partners.

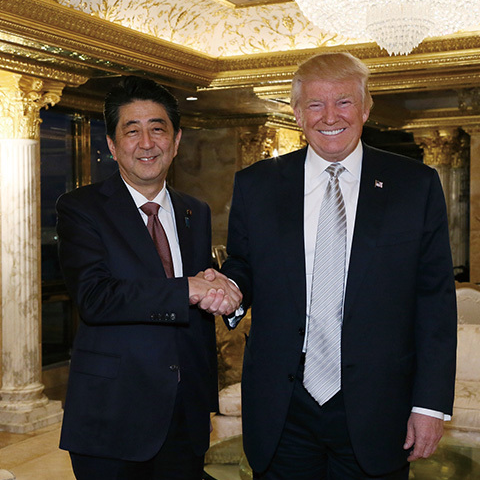

Ralf Annasentz (left), president of Merck’s Japanese operations, and Tsuguto Takeuchi, Onahama Site director.

Pigments developed and produced at the Onahama Site are used in such products as car paints and cosmetics.