History of the Shinkansen

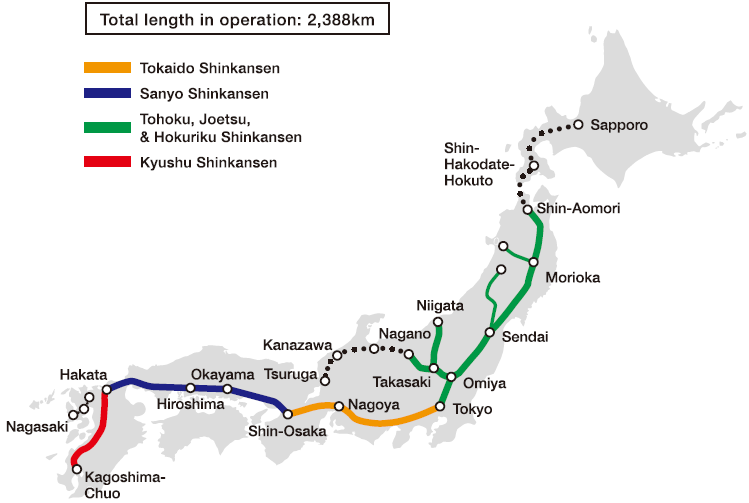

Shinkansen (lit. new trunk line), Japan’s high-speed rail, celebrates its 50th anniversary in 2014, having opened for service between Tokyo and Osaka in 1964. Over the past half century, the made-in-Japan technology behind these sleek trains has continued to evolve. Top speed has risen from 210 km/h (130 mph) to 320 km/h (200 mph), and ridership is now 1 million passengers per day.

Safety Record

Above all else, the Shinkansen has a remarkable safety record. These Shinkansens have now operated for 50 years, over 18,000 days, without a single passenger casualty. This is a testament to uncompromising attention to quality in the development of the technology and strong efforts for safety in operation by all staff involved—from the train operators to the engineers who maintain the trains, tracks, and other equipment.

The strong safety record attests to their focus on disaster prevention. The Shinkansen’s earthquake warning systems have always functioned well to stop the trains safely.

The Japanese insistence on quality is well established. Particularly in matters of public safety, Japan is known for its uncompromising stance and its perennial drive to improve. Japan takes pride in the Shinkansen’s record of zero fatal passenger accidents. Everyone concerned will strive to maintain this unblemished record.

Reliability, On-Time Service, Passenger Comfort, Transportation Capacity

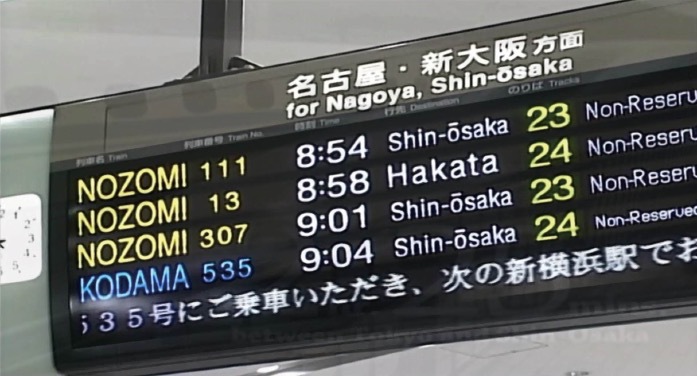

Reliability is another achievement of the Shinkansen, which is renowned for its on-time service. The system is supported by all manner of hardware and administrative systems, including specially designed high-speed rail tracks, automatic train control (ATC), and automated train schedule management, to ensure that the trains run on time. A careful melding of hardware and software allows this equipment—combined with the finely honed technical skills of the operators—to control the trains down to the second, and to ensure precision and reliability in operation. As a result, this system makes it possible for the trains to run at such very tight, three-minute intervals, without schedule delays, averaging less than one minute in duration.

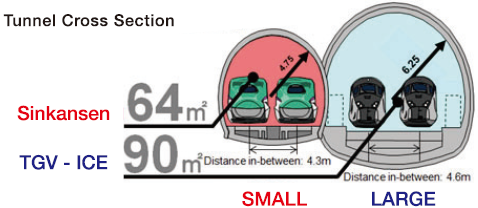

The Shinkansen is also noted for what it has to offer in terms of passenger comfort and transportation capacity. The train’s tilting mechanism to lean into curves at high speed and the high-quality airtight body minimize vibration and provide a smooth, quiet ride. The large body of Shinkansen cars, which are wider than those of other high-speed trains, offers comfortable, wide passenger seats while ensuring large passenger capacity; the standard 16-car train can carry more than 1,300 passengers. This is only possible because from the very beginning, the facilities were designed to be used exclusively by high-speed trains. Thus, the Shinkansen has advantages over other countries’ rail systems, which have been developed under constraints imposed by the standards of existing tracks.

The view inside the Shinkansen General Control Center. Thanks to the support of its staff and the expertise of the highly qualified operators, the Shinkansen maintains reliable service on a tight schedule of departures at three-minute intervals.

Keeping Down the Total Life Cycle Cost of the Shinkansen

To ensure sustainable operations, it is important to reduce costs in a number of different ways.

First are the initial costs. Since Japan’s geographic terrain is rather rugged, Japan has become very adept at building a relatively compact railway infrastructure. The airtightness and aerodynamic design of the Shinkansen made it possible to make the facilities compact compared to high-speed rail systems elsewhere; for example, small-sized tunnels, compact layout, and a short distance between tracks. Features like this help keep down construction costs.

Next are the maintenance costs. For example, compared with rail beds made of gravel, concrete rail beds have a higher initial cost but a much lower maintenance cost, which means the investment can be recovered in eight or nine years. The Shinkansen system aims to strike the right balance between initial costs and maintenance costs, optimizing the total life cycle cost.

Effects of Shinkansen Infrastructure and Station Development

By greatly reducing travel time, the Shinkansen has had various economic benefits. It allows people to spend more time at their destination, increasing their opportunities to consume goods and services there. Moreover, by expanding people’s “range of activity,” the Shinkansen has enlarged the commutable area, increased visitors to tourist destinations, and heightened the value of real estate assets. In this way, the Shinkansen has had valuable business effects throughout its service area. For example, economic growth in Kagoshima Prefecture at the southern tip of Kyushu, 1,200 km away from Tokyo, which is now the southern terminus, was estimated at more than JPY46 billion (USD430 million) when Shinkansen service was extended to southern Kyushu in 2011.

In recent years, there has been a boom in “in-station retailing business,” where railway station buildings have been redeveloped as shopping malls to better serve the needs of passengers. Shinkansen stations now feature vast arrays of restaurants, clothing boutiques, newsstands, and other businesses. For passengers, railway stations are no longer just transit points; they are places to enjoy, through shopping, dining, and other activities. The economic benefits of the Shinkansen lie not just in shortening the travel time; the positive effects are tangible in the businesses that have been established in station buildings throughout the system.

Overseas Development of Shinkansen

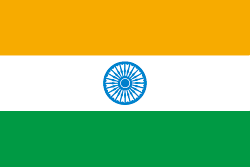

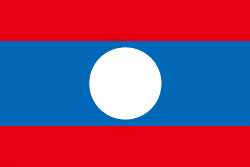

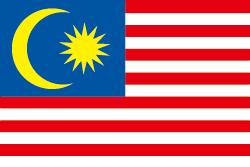

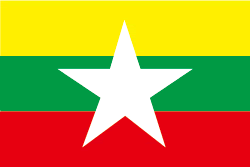

Based on Japan’s positive experience with the Shinkansen, we are working hard to bring these same benefits to other countries. We are not simply trying to export “high-speed rail” hardware. We want to introduce the Shinkansen along with the know-how we have accumulated over the past fifty years, including expertise in safety of operations, in efficient maintenance and operations, and also—importantly —in training the personnel who support the whole system. Japan is a nation where natural disasters such as earthquakes and typhoons are all too common, and we have learned a great deal about how to prepare for such calamities and how to recover from them. We also have knowledge to offer about developing businesses in the areas surrounding rail facilities. By sharing our knowledge and expertise, we wish to make a contribution to the development of many other nations.