The prevention of workplace accidents is of paramount importance for employers trying to protect their staff’s safety. With global temperatures rising steadily due to climate change, heatstroke prevention among workers is becoming an increasingly urgent issue. In response, a Japanese manufacturer of electric components and a construction company have jointly developed a safety system. The system allows monitoring of workers’ physical condition simply by attaching a compact sensor device to their helmets, and its adoption is growing throughout Japan.

The device’s lightweight design ensures it does not interfere with workers’ tasks. MURATA MANUFACTURING CO., LTD.

In fields such as construction, civil engineering, and steel manufacturing, digital transformation (DX)—the enhancement of business procedures through digitalization—is being actively adopted to improve productivity and ensure worker safety. One such example is the Worker Safety Monitoring System, jointly developed by Murata Manufacturing Co., Ltd., a Kyoto-based electronics manufacturer, and Toda Corporation, a general construction company headquartered in Tokyo.

The system consists of a small sensor device attached to workers’ helmets to measure biometric data and surrounding environmental conditions, allowing site supervisors and office staff to remotely monitor workers’ safety.

The impetus for the system’s development came when a Toda Corporation technical development representative approached Murata Manufacturing with a request to help prevent worker heat stress. At many of Toda Corporation’s construction sites, the sheer number of workers sometimes led to heat-related illnesses going unnoticed until they had already become severe.

Previously, Wet Bulb Globe Temperature (WBGT) meters were installed on-site to monitor working environments, with supervisors frequently making the rounds to check on workers individually. Despite these efforts, incidents of heatstroke continued to occur.

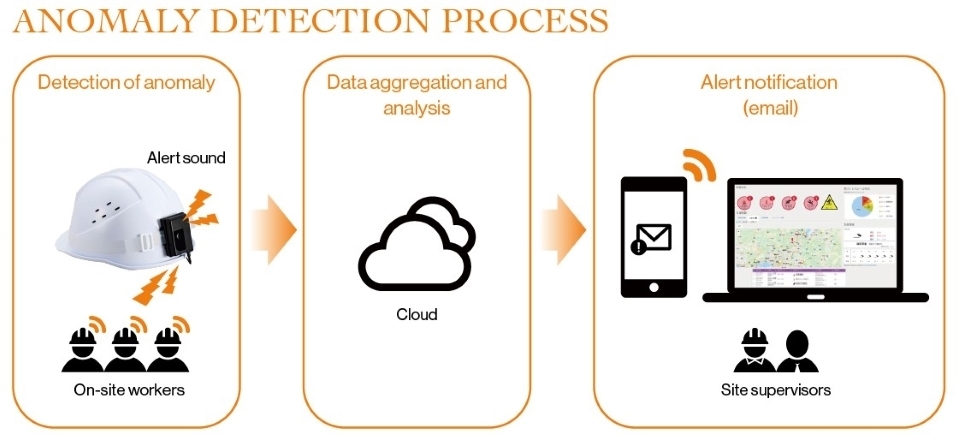

In response to Toda Corporation’s request, Murata Manufacturing’s product development team turned its attention to workers’ helmets themselves. They devised a method utilizing two sensors, one placed at the front of the helmet, where it touches the wearer’s forehead, to measure pulse and intensity of physical activity, and another outside the helmet at the back to record the ambient temperature and humidity. The collected data are sent to the cloud for aggregation and analysis.

The sensor device is designed to attach to a helmet. The sensor positioned at the forehead (indicated in the left image’s helmet brim), measures pulse and activity intensity, while the rear-mounted sensor (right image) measures ambient temperature and other conditions.

If the system determines that a worker is at risk of heat stress, an alert notification is sent to supervisors via email, and the worker’s location is displayed on a map on the supervisor’s computer. At the same time, the worker’s sensor device emits a warning buzzer to indicate possible danger.

The development team began research in 2017, refining the prototype through tests at Toda Corporation’s construction sites. Initially, the device weighed about 200 g, and workers found it “too heavy.” However, by the time the system was first released in 2019, they had succesfully reduced the weight to 100 g. Continued improvements have reduced the weight to 70 g as of 2025. Murata Manufacturing’s TANAKA Toshiki, one of the developers, remarked, “We have improved the product by listening to feedback from the field, and aim to make it even lighter.”

TANAKA Toshiki of Murata Manufacturing Co., Ltd., who is involved in product development for the device.

Since its launch in 2019, the Worker Safety Monitoring System has spread throughout Japan, with more than 10,000 sensor devices being used across over 100 companies. According to Tanaka, companies that introduced the system have reported that cases of heatstroke have been totally eliminated. Workers themselves also praised the system, commenting that it has helped them recognize heat stress symptoms they would previously not have noticed, allowing them to take preventive action.

The system detects more than just heat stress: it can also recognize whether a worker has fallen or collapsed by the duration of the device’s tilt and subtle body movements. When a fall is detected, the system sends alerts in the same manner as with heat stress detection, displaying the worker’s location to supervisors.

Tanaka, who frequently visits client companies to gather feedback for product development, said, “During a recent visit, I was told that a worker had collapsed on account of a pre-existing condition while working alone. They said that if only they had introduced the system earlier, they might have been able to notice sooner and save him.”

Aiming to expand the system’s use in more workplaces, Murata Manufacturing has begun market research in Asia. Tanaka’s ultimate goal is to have the system introduced at numerous job sites, both domestically and overseas, and expressed his strong commitment, saying “By deploying our system as soon as possible, as widely as possible, I want to help minimize the incidence of serious workplace accidents—even if just by one.”