Ammonia has wide-ranging applications, such as fertilizer or other chemical products, and has been garnering attention in recent years as a zero-emission fuel. Tsubame BHB has developed a small-scale plant that can synthesize ammonia at low temperatures, low pressure, and low cost. What innovations is the company eyeing for the future?

Ajinomoto Co., Inc., a Japanese food company and Tsubame BHB shareholder, made its factory in Kawasaki City available for the installation of the startup’s pilot plant. In operation since 2019, the plant produces 20 tons of ammonia a year at a steady pace.

As ammonia contains the nitrogen necessary for crops to grow, it is widely used as a raw material for fertilizers as well as for other chemical products. Also, since it does not emit CO2 during combustion, the material has been attracting attention in recent years as a next-generation fuel for decarbonization.

The production of ammonia requires a high-temperature, high-pressure environment to induce a reaction between nitrogen and hydrogen. That is why mass and centralized production at large plants has been the norm. Developing countries that cannot afford such large-scale facilities are forced to bear the high cost of transportation and storage.

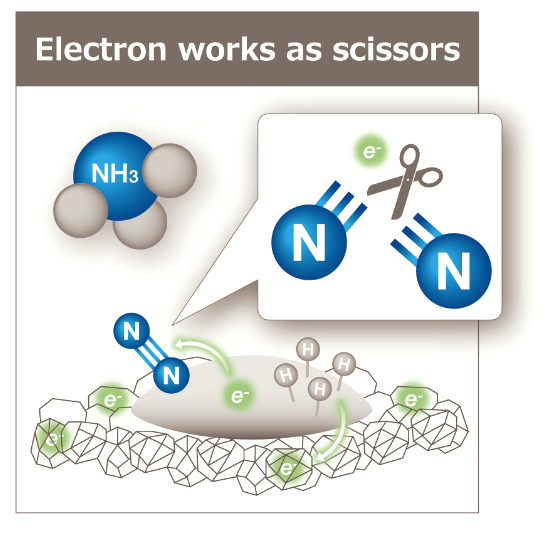

In an electride catalyst, electrons act as anions and behave like scissors to separate tightly bound nitrogen molecules at low temperatures and pressure.

Tsubame BHB Representative Director & CEO NAKAMURA Koji (right) and marketer SUDA Hiromi (left). Its first commercial small-scale ammonia synthesis facility for a demonstration test of hydrogen and ammonia production in Kashiwazaki City will begin operation in August 2025. “With global interest in ammonia growing, it is critical to stay ahead of the curve, so we are determined to make a strong case for commercialization,” says Nakamura.

Hosono’s research was grounded in his desire to create technologies “essential for life.” Tsubame BHB, founded in 2017, inherited that concept and embraced the mission of using creative technologies to solve human issues related to the environment and food. According to Tsubame BHB Representative Director & CEO NAKAMURA Koji, “In order to eliminate the world’s food imbalance, what’s crucial is to develop small devices that can easily make the required amount of ammonia on site.” The company’s pilot plant, which can produce 20 tons of ammonia a year, has proven that the catalyst is stable, enabling the company to move faster toward commercialization.

Small-scale, on-site production would also facilitate the production of green ammonia from hydrogen produced by renewable energy sources. For example, in Laos—which has abundant hydropower—Tsubame BHB has been involved in a project to investigate the profitability of locally produced green ammonia from surplus hydropower for local consumption with the cooperation of the country’s Ministry of Energy and Mines. “The Lao government is committed to agricultural development to help Laos graduate from its position as a least developed country. We would be happy if our technology could contribute to both productivity gains and decarbonization,” said SUDA Hiromi, who is in charge of the company’s marketing and business development in developing countries.

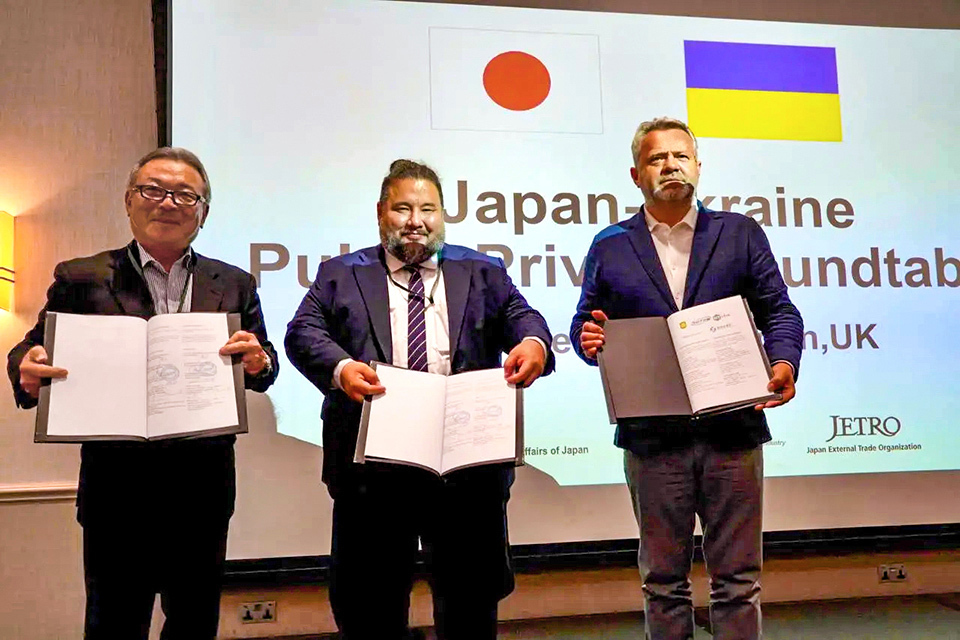

In conjunction with the Ukraine Recovery Conference held in London, Japan’s Ministry of Economy, Trade and Industry, the Ministry of Foreign Affairs, and the Japan External Trade Organization co-hosted the Japan-Ukraine Public-Private Roundtable, at which a memorandum of understanding (MOU) was signed for the Green Industrial Zone Project in Bucha, Ukraine. The event, attended by around 120 participants from Japanese and Ukrainian industries, confirmed the promotion of partnerships between the public and private sectors as well as between companies from both countries.

In May of this year, Tsubame BHB announced its involvement in the Green Industrial Zone Project in Bucha, Ukraine, which aims to make hydrogen and ammonia from renewable energy for use in electricity generation and fertilizer production. The startup is partnering with the Polish hydrogen system designer Hynfra and the Ukrainian engineering firm UTEM. Tsubame BHB will provide its ammonia-synthesis technology to help Ukraine achieve its twin goals of reconstructing after Russia’s aggression and achieving energy independence.

The current global output of ammonia is insufficient for it to be used extensively as fuel, so it is necessary to expand production at a low cost. Nakamura says, “We will focus on minimizing the size of our facilities for on-site production in developing countries, while at the same time focusing on developing highly efficient catalysts that can be applied to large-scale ammonia plants, with an eye to fuel applications.” Tsubame BHB will continue exploring solutions to this issue affecting all of humanity.