As Indonesia’s economy continues to expand, the numbers of residents and commuters in Jakarta, the nation’s capital, and its environs have been rising, which has brought increased demand for transportation. Japan is providing assistance for the construction of Indonesia’s first subway line to help meet this demand.

In response to requests from KAI Commuter Jabodetabek (KCJ), which operates six commuter rail lines in the greater Jakarta area, East Japan Railway Company (JR East) and other Japanese railways have been supplying retired rolling stock.

Because of this long-standing relationship, JR East decided to dispatch an employee to KCJ in 2015 to offer technical support and management advice. His mission has been to share Japan’s approaches to railway services, including systems for efficient operation of rolling stock and safety improvement. KCJ is aiming to raise daily ridership from the current 850,000 to 1.2 million by 2019, and is energetically seeking to improve its operational know-how. JR East, meanwhile, has been seeking to increase opportunities for its employees to put their skills to work outside of Japan. Therefore, this arrangement effectively created a win-win situation for both companies.

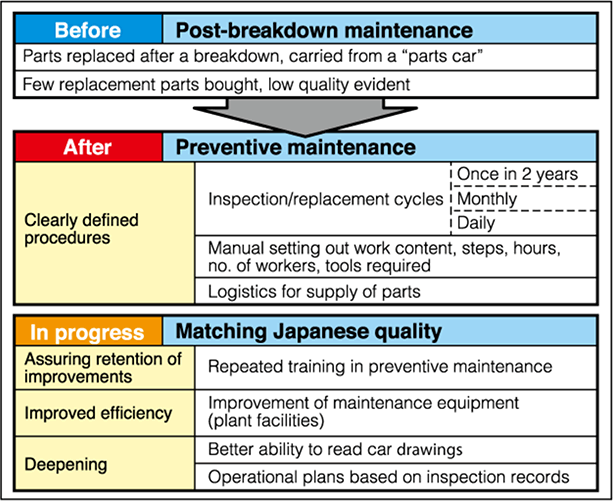

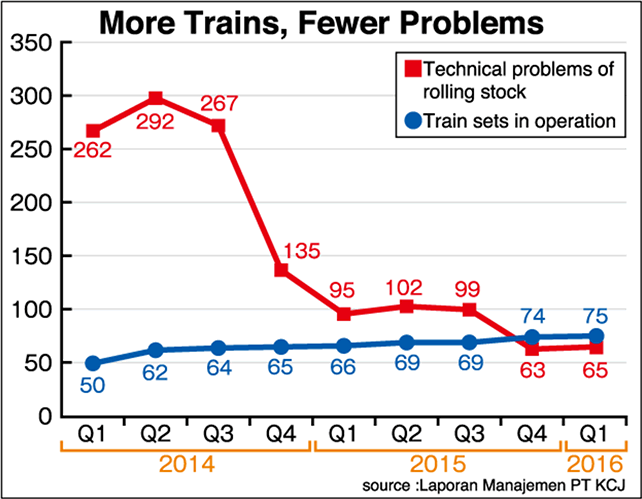

Kengo Maeda, the dispatched employee, started out by exhaustively checking the railway’s worksites, where he found room for improvement in the approach of employees toward maintenance. In Japan, preventive maintenance is the rule, but at the Indonesian railway it was common to fix railway cars only after trouble happened. Because of the lack of proper maintenance, parts tended to wear out quickly, causing operational problems.

Maeda acted as a bridge between management and employees on the front lines, and he conveyed the maintenance methods and procedures used in Japan. Through these efforts he supported the drafting of a new maintenance manual. The standardization and rationalization of worksite procedures resulted in a marked reduction in the number of railway car malfunctions.

One of Maeda’s current projects is improvement of the timetables. Previously, they did not take into account such factors as acceleration and deceleration, waiting times, and speed limits, which resulted in train delays. As a first step, Maeda reduced the frequency of services while maintaining total capacity by increasing the number of cars per train from 8 or 10 to 12. This eliminated the cause of congestion on the tracks and greatly improved the punctuality of services.

Most of Maeda’s initiatives have involved the introducton of procedures that are common in Japan, but he says that they were met with surprise in Indonesia. He declares, “Japan has good railway technology and know-how not just on the hardware side but also in ‘soft’ areas such as safety awareness, inspection and maintenance, and hospitality. I hope we can make this the standard in Indonesia and all around the world.